条件监控:需要还是奢侈?

Do I need Condition Monitoring? Is it a Need? Is it a Luxury?

要回答这个问题,让我们首先回到理解”What is Condition Monitoring?”

条件监控是一个计划收集和评估的过程,以检测系统或其组件的性能或状况的变化,因此可以预先计划纠正措施,以降低维护成本并维护设备/系统的可靠性。

让我们看一下失败模式和统计数据如何说明必要condition monitoring and predictive maintenance strategies。

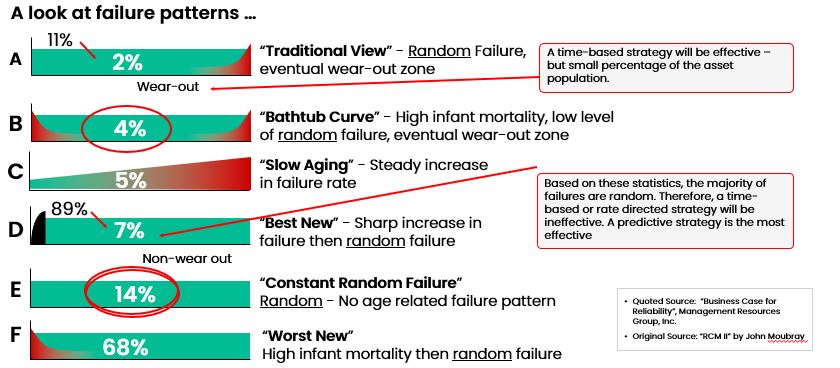

传统的失败观点是,资产及其组件根据可预测的时间间隔磨损。但是,失败统计数据表明,仅占资产总数的比例相对较小(图1)。这项起源于航空业的研究表明,只有11%的故障表现出磨损区域模式,在这种情况下,基于运行时间或日历时间的失败时间可以通过合理的确定性进行预测。对于这些资产,定向维护或维修策略可能是最有效的策略。

如本研究所示,大多数资产,89%,根据服务时间没有可预测的磨损区。这些资产中有很大一部分表现出婴儿死亡率模式,这意味着通过执行不必要的维护或原始设计或制造缺陷来引入许多故障。对于这些资产,预测维护策略是最有效的。因此,在设计和制定维护和可靠性计划时,应选择条件监控和预测维护策略作为这些资产的第一道防线。

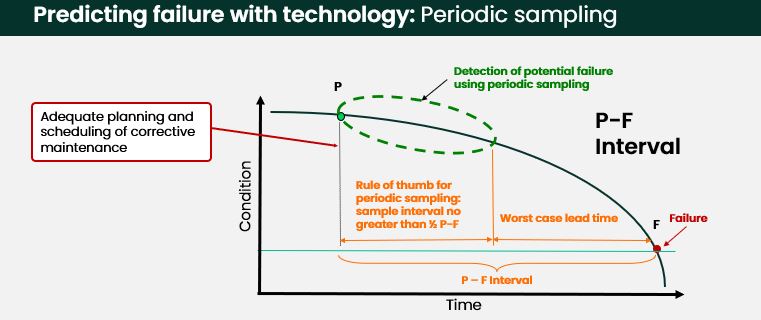

一旦启动故障模式,剩余的失败时间通常遵循可预测的模式。P – F间隔是首先检测到潜在功能故障模式与实际功能故障时(图2)之间的时间间隔(图2)。P-F间隔概念用于设置数据采样间隔,因此有足够的时间计划和安排纠正措施在实际失败发生之前。不同类型的故障具有不同的P-F间隔。例如,滚动元件轴承故障可能的P-F间隔约为2个月(取决于申请)。一个常见的经验法则是将样品间隔设置为估计的P-F间隔的一半。这将使大多数失败得以尽早发现,以便在最小化对企业的影响的同时计划和安排纠正措施。

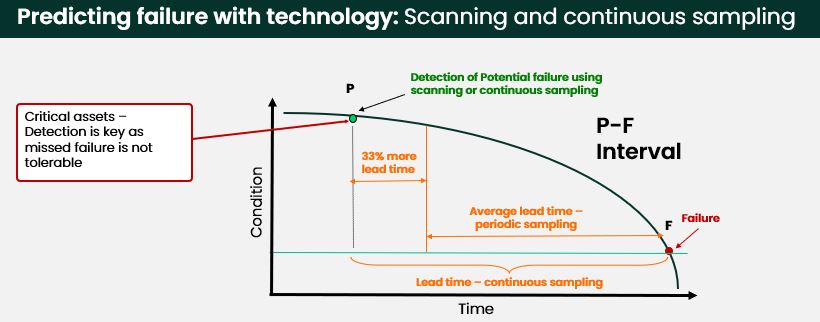

在线的连续和扫描监测系统eliminate possible error sources associated with identifying the best correct P-F and data sampling intervals (Fig 3). On average, continuous and scanning methods also enable earlier detection of potential failures than what can be provided with periodic sampling. As shown above, failures are detected at point “P” with on-line systems, effectively eliminating the time lag associated with periodic data samples. For critical and essential assets where the risk of a missed failure is not tolerable, on-line continuous or scanning condition monitoring methods and the additional diagnostic capabilities they provide are frequently justifiable.

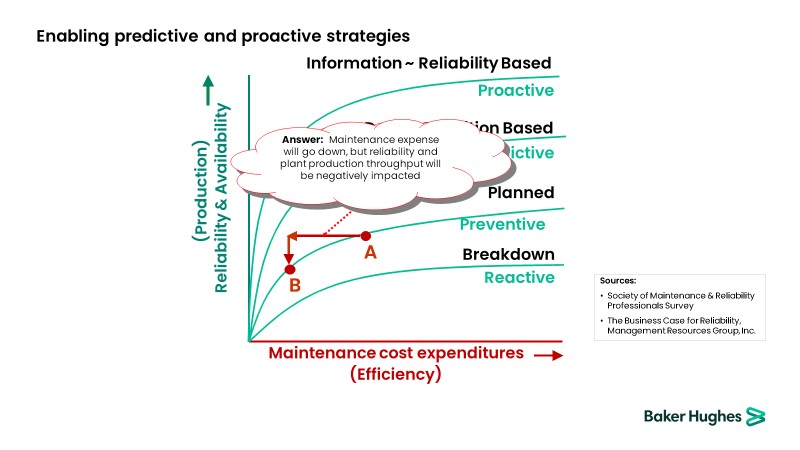

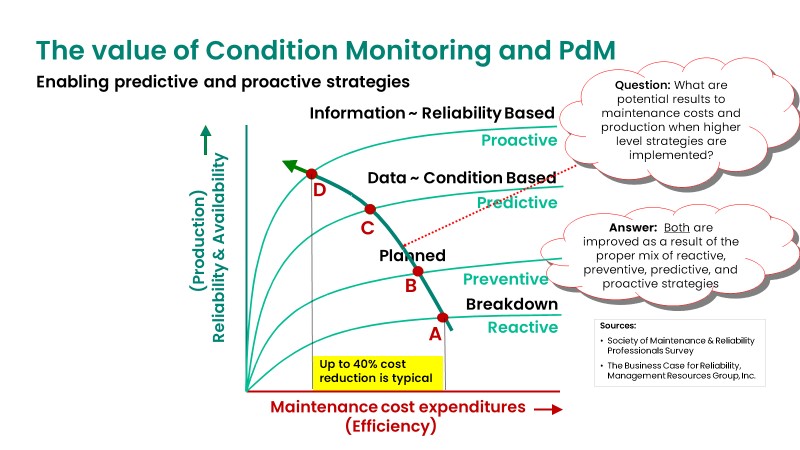

现在让我们来谈谈的价值condition monitoringand predictive maintenance to an organization. This graph describes several relationships between production, maintenance costs, and several types of maintenance and reliability strategies. Many companies are faced with economic pressures that demand reductions in costs in order to remain competitive. Unfortunately, a frequent course of action is to cut maintenance cost expenditures without any change in strategy. Using the example in the graphic by moving from Point A to Point B (Fig 4), reducing preventative maintenance costs alone may achieve the desired results, but this achievement will be short-lived. It won’t be long before equipment reliability and plant throughput will be negatively impacted. More importantly, the safety of plant personnel may be jeopardized due to unreliable equipment.

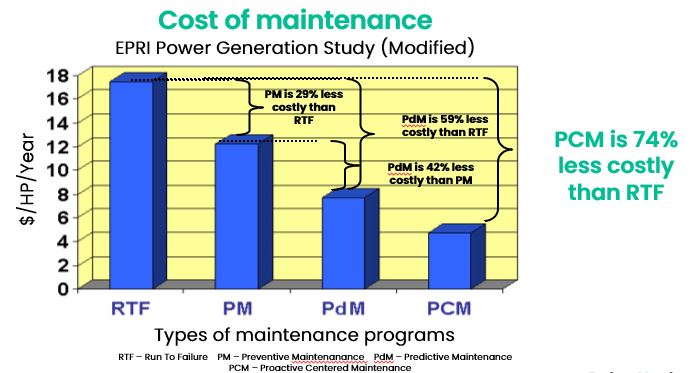

The challenge is to明智地削减成本采用一种结合更高级别的维护和可靠性策略的方法。如点A,B,C和D定义的曲线所示,预测性和主动维护策略可以帮助提高设备可靠性,可用性和植物生产,同时减少维护成本支出(图5)。案例历史表明,降低成本高达40%是典型的,有时已经实现了更多的回报(图6)。条件监控和预测维护计划对于实现这些更高级别的策略并推动这些结果至关重要。

RTF –stands for Run to Failure and PCM – stands for Proactive Centered Maintenance in the EPRI study or “engineering out failure modes”

制定条件监控程序的第一个要求是完整,准确的设备数据库。这包括一个主设备列表,其中包括已识别设备和支持铭牌数据的类和子类。配置路线和样品点时,设备上的相应字段标签也将派上用场。

开发设备数据库后,所有设备必须按照安全性,环境,生产,维护成本和产品质量对相对关键进行排名。每个排名标准的权重根据代表关键工厂功能的团队成员的输入确定,然后使用一致,平衡的标准确定每个资产的排名。

下一步是根据关键性和故障模式将技术分配给资产。This will include development of an on-line condition monitoring plan. Failure mode and effects analysis (FMEA) methods are used to determine what technologies and measurement points are needed to detect potential failure early. For portable periodic sampling, PdM tasks are scheduled based on technology assignments and load-leveled resources allocations.

下一步是解决支持技术PLA所需的人力资源n。无论是内部,外包还是两者的组合,必须传达对角色和责任的明确定义,并且必须满足培训要求以支持所需的技能。有了新的角色和职责,以及指导维护工作的新方法,成功工程文化变革的重要性不可忽视。文化变革方法应与技术计划并行采用,以确保实现和持续的自上而下的承诺。

一旦制定了技术和人力资源计划,就必须制定和实施方法计划。将需要制定和制定计划的政策和程序。这将包括新的工作和信息流程流程,这些过程将反映修订后的组织结构以及新的角色和职责。最后但并非最不重要的一点是,必须制定关键的绩效指标,并制定适当的措施以衡量该计划的持续成功。这些KPI应该包括领先和滞后指标的混合。可以在计划的早期就可以实现领先的指标,例如PDM任务合规性。滞后指标(例如预测维护产生的工作百分比)将显示该计划开始产生影响的结果。

桑卡Ganesh

高级机械诊断服务经理

生物

More than 25 years of experience in the field of maintenance, reliability, condition monitoring and specialized in the field of Machinery diagnostics. Presently the Machinery Diagnostics Technical leader for MENATI region supporting the field engineers for the troubleshooting and