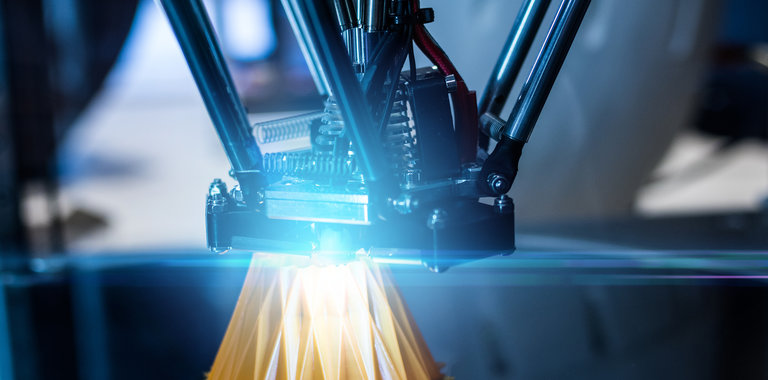

Oxygen and moisture measurement in 3D printing

3D printing is expected to show significant growth in the coming years. The process of 3D printing involves applying layers of fine dust metals or polymers and then fusing the layers with laser technology. The process takes place in the chamber of the 3D printing machine where the environment is closely monitored for oxygen and moisture content. Excess moisture and/or oxygen can lead to oxidation of the feedstock powders and a reduction in the weld strength between layers, leading to premature failure of the components. Oxygen is therefore evacuated from the chamber and displaced with Argon before the laser bonding of the powdered layers begins. For similar product quality reasons, it is also critical that oxygen and moisture are measured in the production of the fine metal powders used as base material.

In both applications there is a significant safety aspect in measuring oxygen and moisture when handling large quantities of powdered metals. Oxygen must be maintained below explosive limits to avoid a dust explosion and so continuously measured. Even without the presence of oxygen and in standard inerting gases such as nitrogen or carbon dioxide, some metals can still ignite.

Moisture measurement is also critical as some metal powders (Al or Mg) will produce hydrogen and steam if mixed. In addition, damp metal powders are extremely dangerous and can produce a strong exothermic reaction leading to steam explosion if not properly identified.

Oxygen and moisture are measured at two points along the 3D printing process, namely in the chamber of each 3D printing machine and at the production location of the fine metal power feedstock.

3D Printing Machine: Each 3D printing machine will have an oxygen measurement and most will be accompanied by a moisture measurement. These measurements are vital in detecting changes in the environment due to leakages, incomplete purges or contamination in base materials, the results of which can lead to a change in the mechanical and chemical properties of the components. These measurements are continuous throughout the 3D printing process where the atmosphere should remain stable except for changeover over events which will require a purging of the chamber.

Metal Powder Manufacturing:在金属粉末生产地点,进行了类似的测量,以避免污染原料产品。制造和储存通常可以发生在惰性气氛中,而氩气是首选气体,鉴于其惰性特性和高密度比与氧气的比率。标准屈服于二氧化碳或氮之类的气体可能无效,因为某些金属仍可能点燃。

Benefits:

- Low maintenance and calibration requirements

- Compact designs with integrated display

- Fast response times and no background interference

- Proven field performance in similar applications

- Proven fuel cell technology

The challenge in OEM manufactured 3D printing machines lies in the size and reliability of the transmitters and their measurements. Space in 3D printing machines is a premium and so the measurement solution must have appropriate form factors and be free of interference from background gases such as nitrogen or argon. Printing times can be hours or days and so the transmitters must operate without the requirement for intervention while having a fast response time to allow the operator time to respond to changes in the internal chamber.

oxy.iq非常适合使用Veridri OEM溶液测量水分时的氧气测量。两种发射器的尺寸都适当地尺寸,并具有氧气的集成显示和控制。IQ为操作员提供易于校准和维护。此外,两个发射机的响应时间在通过氧气或水分中断的破裂和典型的背景气体在此过程中对测量的可靠性没有影响。

Moisture

- Range: 0 - 1000 ppmV

- Nominal: 50 ppmV

Oxygen

- Range: 0 - 1000 ppmV

- Nominal: 50 ppmV

Download the application note here