系统1用例:复杂的变速箱监视

在现代流程密集型行业,控制和保护系统是关键机械管理的骨干。这些系统与使用它们的人员一起是对意外安全,环境和生产力问题的第一批响应者。

高级工厂操作员了解,其在边缘关键机械控制和保护系统收集的全面数据集可以进一步用于主动监控机器状况和传感器健康。此类数据对于机器故障后的任何反应性根本原因调查也至关重要。没有公司做的超过内华达州弯曲to promote and advance the understanding of机械保护和状况监测based on data-driven analysis. Machinery knowledge collected over Bently Nevada’s 60+ years of research and experience informs the asset type use cases embedded in the development of our flagship condition monitoring software platform, System 1.

在本文中,我们关注系统1 Evolution的增强功能,以收集,分析和可视化复杂机器变速箱的数据,包括有关其成功使用的案例研究。

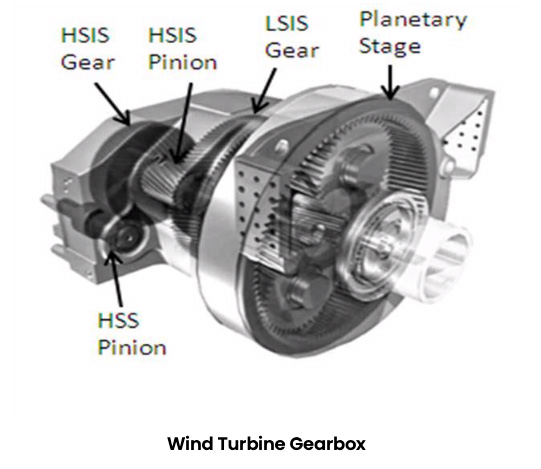

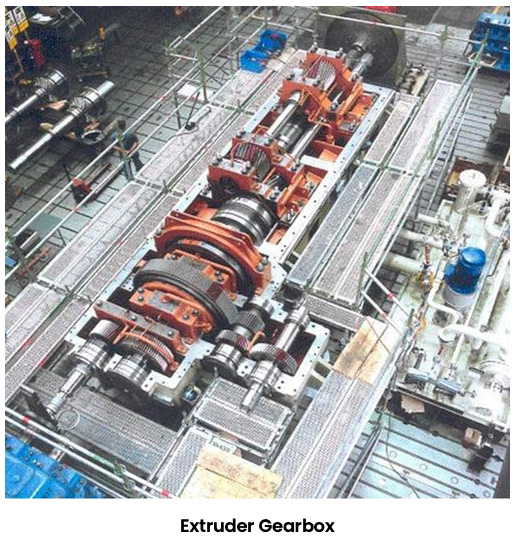

The role of a gearbox in the overall machine train is to change shaft speed and torque while transmitting power from the driving to the driven machine. Consequently, gearbox requirements are largely dictated by the characteristics of the coupled machines. A parallel gearbox like the one pictured above is appropriate when the ratio of input to output speed is moderate and space is not limited. This gearbox consists of a single stage – a stage being a set of gears that accomplish one increment of rotational speed change.

In applications where a large speed ratio is necessary and/or when the input or output torque is high, a complex gearbox is used. This gearbox could consist of multiple parallel stages, as often found in extruders in a polyethylene process and machines used for reduction and forming in metal and mining processes. When space is at a premium, epicyclic (aka planetary) gearboxes are often employed, wherein multiple intermeshing gears are nested concentrically. There are several sub-categories of planetary gearbox design, but they all have a smaller volume than parallel gearbox designs for the same power transmitted, and coaxial input and output shafts (ref. 1). Planetary stages can be combined with parallel stages in the same gearbox. Complex gearboxes are a main component in thousands ofwind turbines全球运营。下图显示了由行星和两个平行阶段组成的三阶段风力涡轮机变速箱。

为了使变速箱可靠地操作,齿轮需要正确的冶金和尺寸,铸造和加工,并且必须在其设计范围内正确组装,安装(粉底和安装),对齐,润滑和操作。其中一个或多个的问题,如果未被发现,可能会导致变速箱故障。复杂的变速箱故障可能是机器列车中最昂贵的问题,不仅在维修/更换材料和人工方面,而且在停机时间和生产损失方面。好消息是,当问题开始发生时,变速箱通常会通过噪声和/或振动传达其遇险。

Gearbox failures result from bearing, rotordynamic, and gear mesh problems, and a problem in one area can develop into a problem in another. Problems with gear mesh can be elusive for several reasons. Multistage complex gearboxes have internal intermediate gears and shafts rotating at various speeds, and can have more than two meshing gears per stage. In planetary gearboxes, some of the gears (and therefore the mesh locations) are constantly moving with respect to a case-mounted sensor. Furthermore, the gearbox may be undergoing speed and/or load changes that will vary the amplitude of vibration by which gear condition and alarm levels are determined.

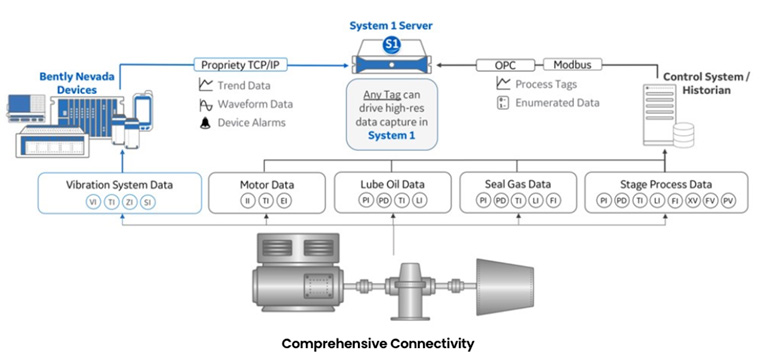

在变速箱中检测滚动元件轴承(REB)或流体膜轴承(FFB)问题与其他类型的机器没有什么不同,该机器通过reb或轴径向和轴向位移波形和/或位置来实现。FFB的更改。这些工具是系统1的基础,在任何条件监控系统中都存在一个或另一个程度。另一方面,齿轮需要特殊的采样,过滤和机载分析来逗弄关键的健康指标。一些专门的保护/监视边缘设备内置了这些功能,但是在大多数通用机械保护系统中都缺乏这种复杂水平。为了有效,世界一流的状态监测系统必须具有宽度和灵活性,以使用各种边缘设备来检测轴承,动力和齿轮问题,以促进早期检测和根本原因识别。System 1已演变为包括连接性,分析和可视化功能,以处理无数的变速箱设计,操作条件和用户需求。

在许多工业设施中,单个条件监测系统被要求处理许多类型和关键水平的机器。有些机器需要保护系统,而另一些机器仅需数据采集, and the level of criticality dictates different amounts and intervals of data. System 1 can interoperate with a variety of Edge devices that provide not only dynamic vibration signals, but proportional values corresponding to process conditions and discrete inputs corresponding to operating states.

内华达州的几个弯曲的内华达边缘设备具有一系列保护和/或条件监控功能,适合在复杂的变速箱上使用。选择取决于几个因素,包括驾驶员和驱动的机器类型,关键性排名以及故障模式是否需要连续,扫描或便携式监视方法。对于有效的变速箱条件监视,Edge设备应具有同步采样和/或基于订单的速度跟踪的钥匙重点或速度信号,以及将波形数据发送到系统1的能力1.对于具有不同负载的机器列车来自机器控制系统的输入允许在振动级别和机器负载的系统1中进行视觉相关。负载还可以用于定义单独的机器状态,以确定何时以及如何将分析和警报应用于测量值。径向和轴向轴承金属温度和油温也是轴承和齿轮健康的重要指标。

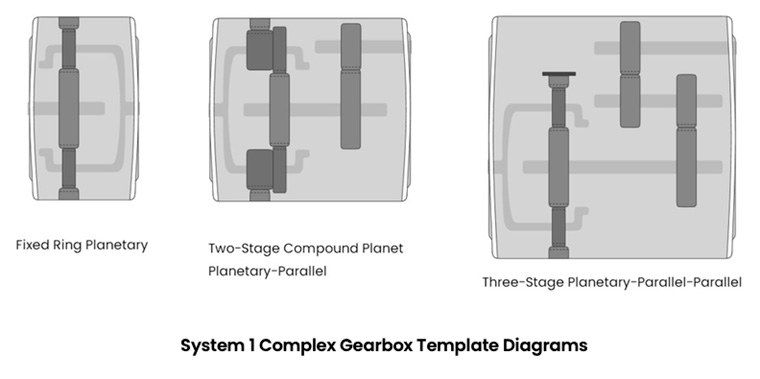

一旦确定了边缘设备,条件监控系统就必须建模每个变速箱的构造和特性。系统1的17.1版(2017年5月发布)引入了变速箱模板和配置工具集的完全配置的变速箱。复杂变速箱模板的图像如下所示。配置过程包括将变速箱纳入机器火车布局,命名和关联轴和齿轮,以及输入轴承和变速箱属性以及运动学信息。这通常是由调试服务团队为用户完成的。基于这些输入,软件会自动确定高级健康评估所需的轴速度,齿轮级比率以及轴承断层和齿轮网频。

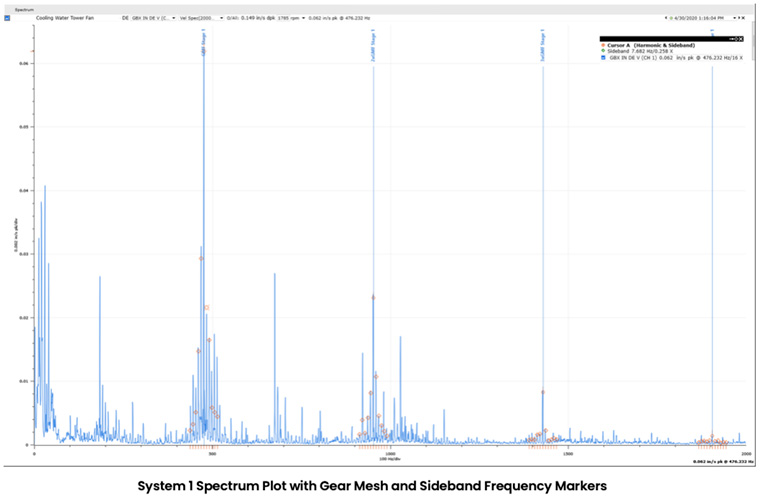

The most salient vibration characteristic of gears is typically their mesh frequency (periodicity of tooth contact as they pass through mesh) and the first two or three integer multiples (harmonics) of that fundamental gear mesh frequency (GMF). Based on the configuration discussed earlier, System 1 allows the user to configure a bandpass measurement around one or more of the gear mesh frequencies. One peculiarity of some planetary gearboxes is that the highest amplitude spectral component does not appear at the GMF location(s), but instead one or two multiples of gear rotation speed to either side (ref. 2). Details like this must be considered when incorporating analytics into a condition monitoring system.

虽然齿轮网频是一个有用的指示器,但基本网格频率的幅度可能随变速箱负载而变化,并且带通道和整体测量值可以由它们主导,从而掩盖了任何较小但有用的光谱成分的变化。事实证明,一项光谱特征在早期识别齿轮钳位的情况下是有用的,是边带,它具有识别舞台上哪个齿轮的额外优势。下面的频谱图从两阶段冷却塔变速箱的第一阶段显示出围绕基本齿轮网频及其三个谐波的边带(由橙色标记叠加层标识)(由蓝色标记叠加层识别)。

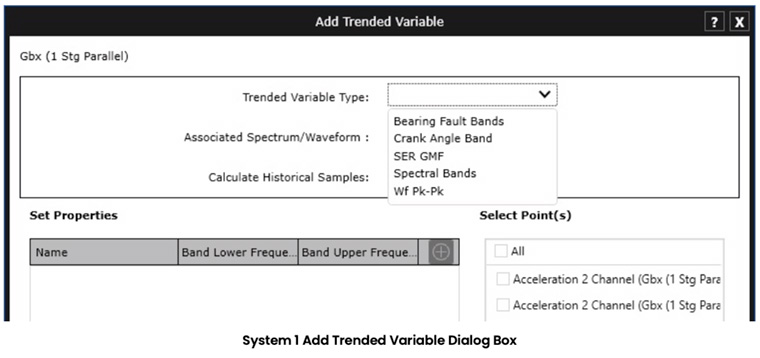

为了有效地将边带作为分析性,内华达州开发了一种专利的算法,称为边带能量比(SER)(参考文献3),在系统1版本17.2中添加。Ser算法可以在同步(首选)或高分辨率异步波形上执行。SER可以在下面的选择列表中以及光谱带和轴承断层带中看到。选择这些中的任何一个都会根据先前输入的变速箱属性自动配置新变量,并将其添加到选定的点。添加时,将对与测量点相关的每个阶段的1倍,2x和3x GMF的传入数据进行SER分析。还为用户提供了将SER分析应用于该点的历史数据的选项。

一旦定义了测量和分析,设置适当的软件警报阈值的能力对于系统的有效性至关重要。System 1的统计警报功能和警报快速配置功能使用户可以使用历史数据和统计计算参数自定义单个或积分组的警报。

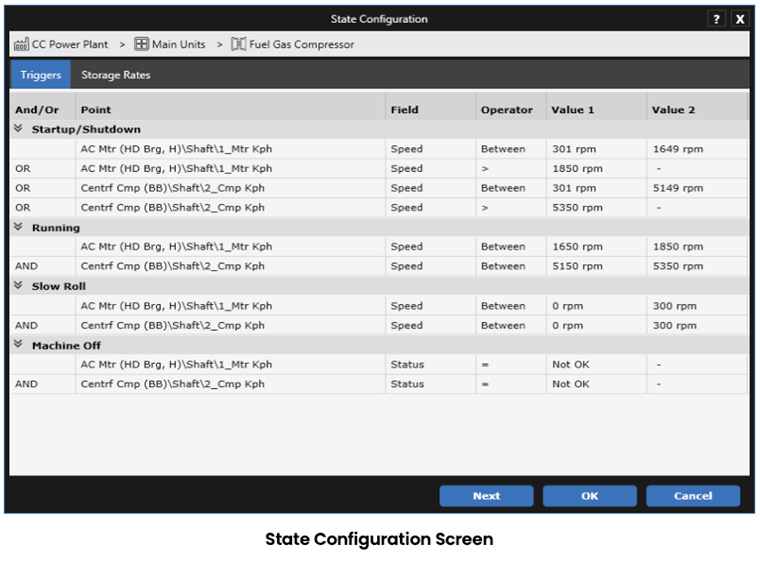

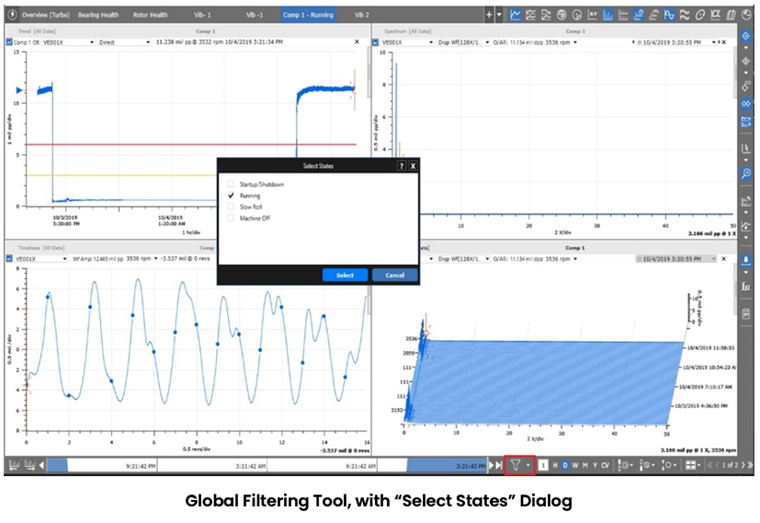

如果机器以不同的速度或负载运行,则系统1允许用户将软件警报限制为用户定义的机器状态,并为每个操作状态设置不同的警报阈值。这包括警报抑制功能,以便在状态更改之间进行读数之间的时间,以便在新状态的警报阈值重新启用警报之前稳定。

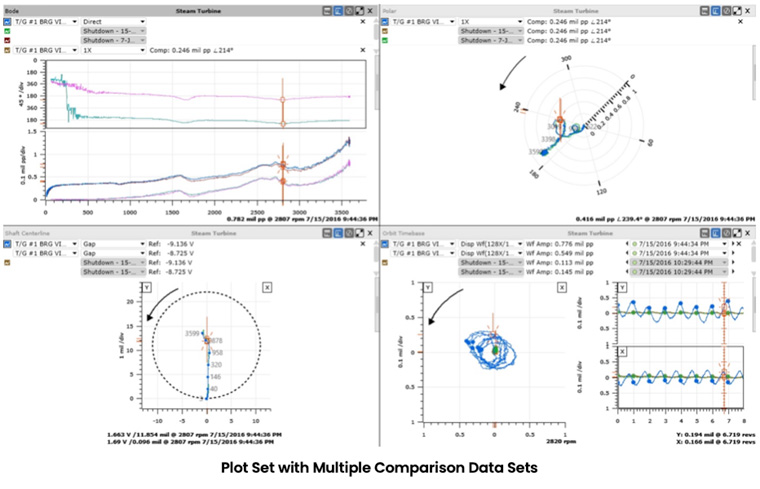

如果没有以用户友好的界面和符合用户的工作流程的用户友好界面以及有意义的绘图格式来强调关键特征和信息的有意义的绘图格式,则所有前面的连接性和分析都是徒劳的。系统1的可视化功能通过从前几代软件和广泛的用户反馈中学到的课程进行了完善和增强,从而提供了无与伦比的效率和有效性。

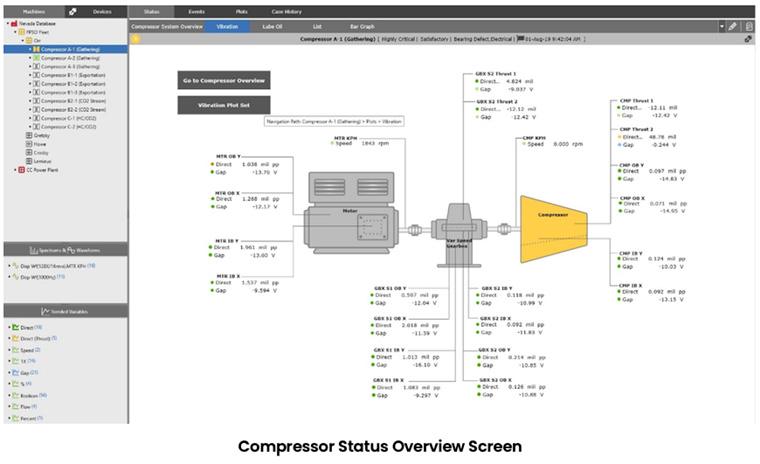

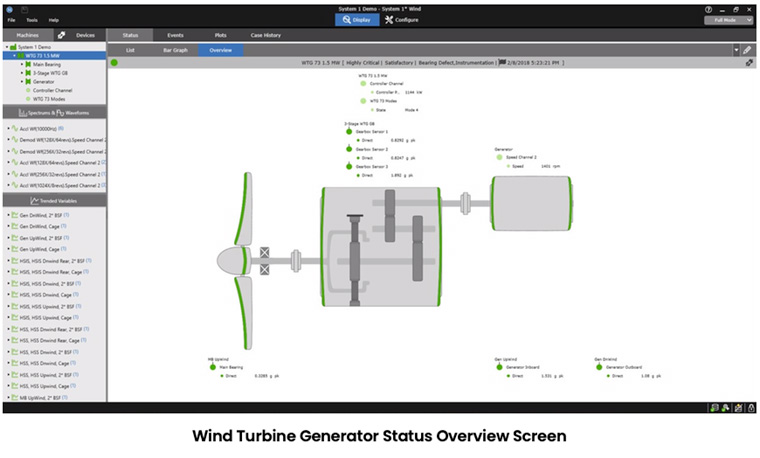

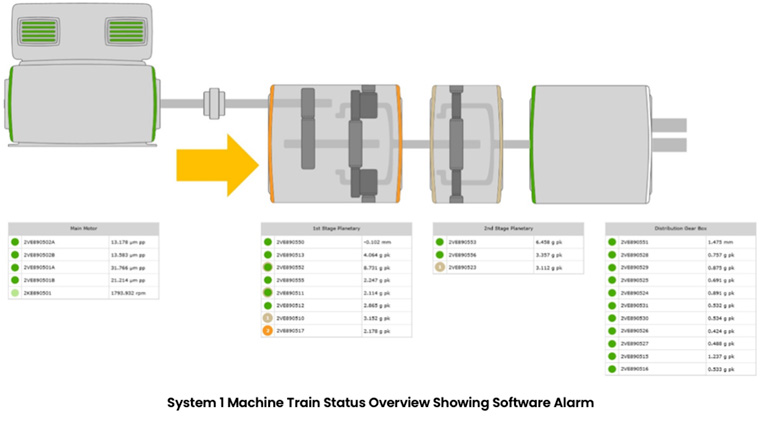

To quickly comprehend the status of a machine, users typically begin with the Status Overview, which provides an intuitive understanding of levels and alarms. System 1 allows users to create multiple Diagram Views – up to 50 per machine train – each with its own unique page tab. The interface is totally customizable, including the ability to add or delete measurements from the diagram, rearrange measurement locations, modify the text/background colors, add navigation buttons as links to other tabs and sub-tabs, and even replace the standard machine shapes with the user’s own image and color-coded alarm status icons.

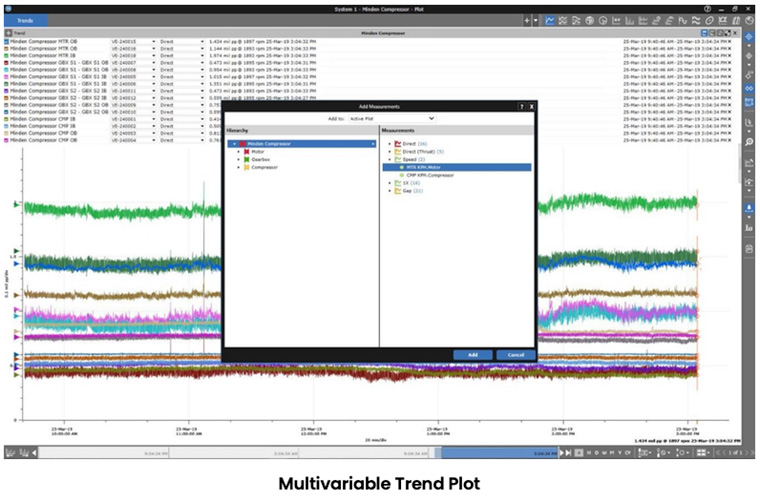

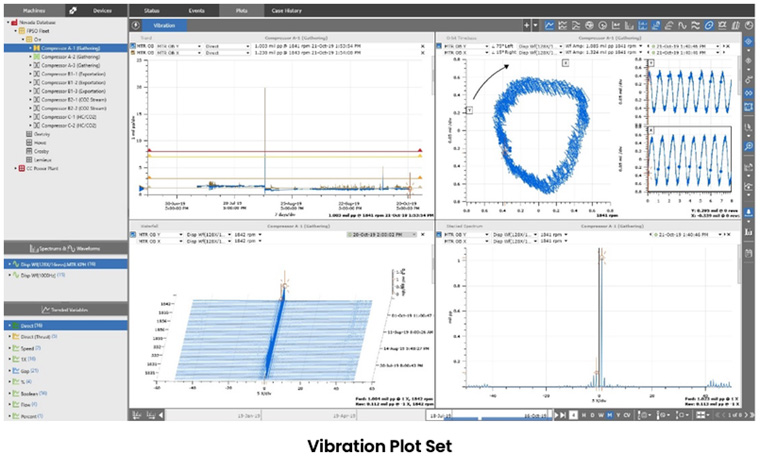

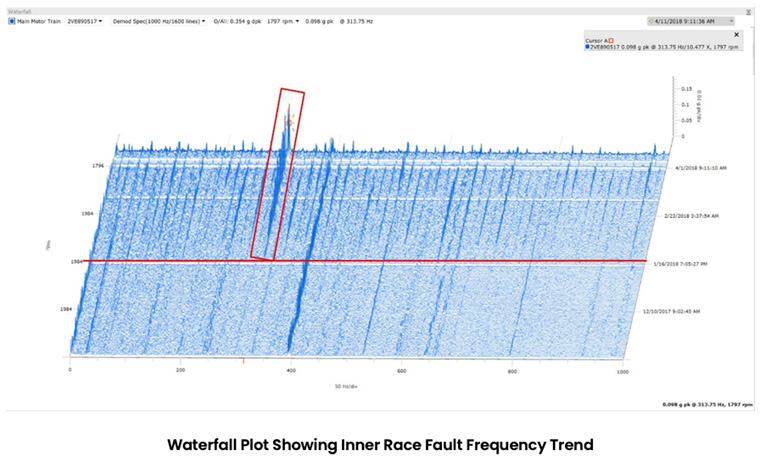

如前所述,变速箱中的问题至少可以从三个不同的区域开始,因此可视化工具必须为用户提供功能,以便快速将多个变量的趋势相关联并轻松地绕过不同的绘图类型。调查问题通常是从事件列表中单击警报开始的,该列表立即打开一组相关图。从那里开始,System 1提供了多功能的绘图工具,可以快速添加从齿轮,轴承和轴位置测量到绘图的变量,以便于趋势比较和相关性。光标和缩放的绘图同步功能使得易于查明有意义的更改和偏差。

For gearboxes under varying loads and/or speeds, it is important to visualize data separately for each configured operating state. State-based data filtering within the Plots workspace is available for System 1 installations with PostgreSQL as the historian, and is applicable to all plots except polar, bode, and shaft centerline. This capability can be applied both globally within a plot set and on an individual plot.

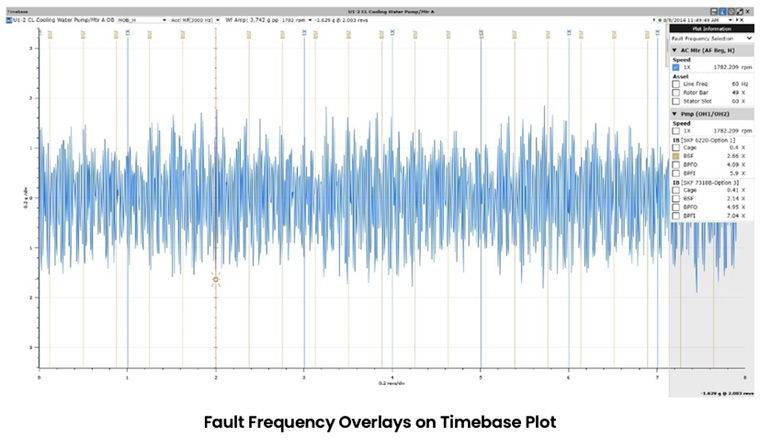

两个有用的图覆盖功能适用于变速箱条件可视化:

- 故障频率标记可以叠加在频谱,时态和堆叠的时间库图上

- 多个保存的比较数据集可以在图工作区中叠加。

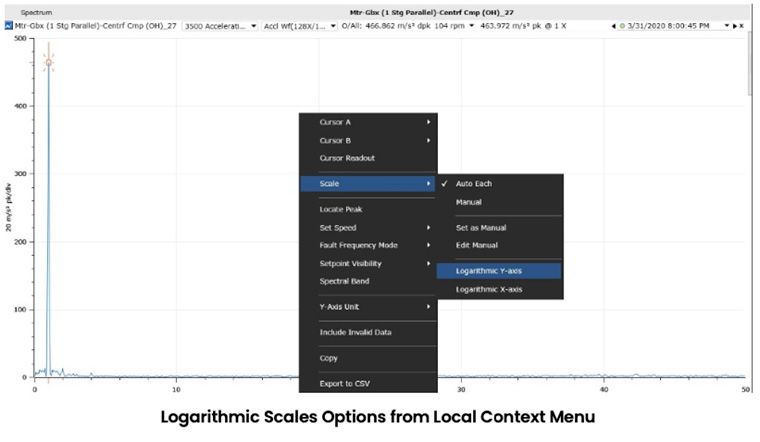

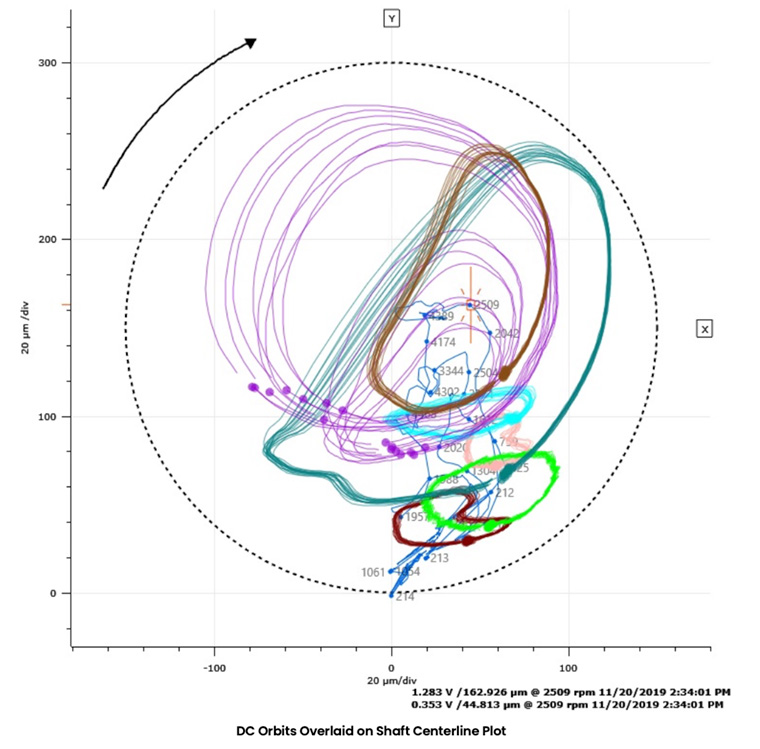

系统1的20.1版包括两个与变速箱诊断相关的令人兴奋的新可视化功能:

- Logarithmic scales for Spectrum, Stacked Spectrum, and XvsY plots

- DC轨道叠加轴中心线图。

条件监控系统的无件好处是能够检测和纠正关联的传感器和机械保护系统的问题。除了软件中的传感器OK状态外,系统1中的时间键和频域图允许用户检测可能指示接线问题或传感器失败的噪声或间歇性传感器信号。这些图还显示了机器正在展示的振动,提供了实时经验数据,以优化保护硬件中的过滤器角,振幅警报和其他设置。

By combining its connectivity, analytics, and visualization capabilities, System 1 can detect bearing, rotordynamic, gear mesh, and other common problems in complex gearboxes, making it uniquely suited for any and all machinery assets with a gearbox.

以下案例研究显示了系统1如何帮助一个用户改善对其复杂变速箱的监视并防止昂贵的损坏(参考文献4)。

在公司大规模挤出机变速箱发生重大故障之后,呼吁内华达州的一支矮胖团队设计和安装条件监测系统,该系统将警报并防止未来昂贵的崩溃。

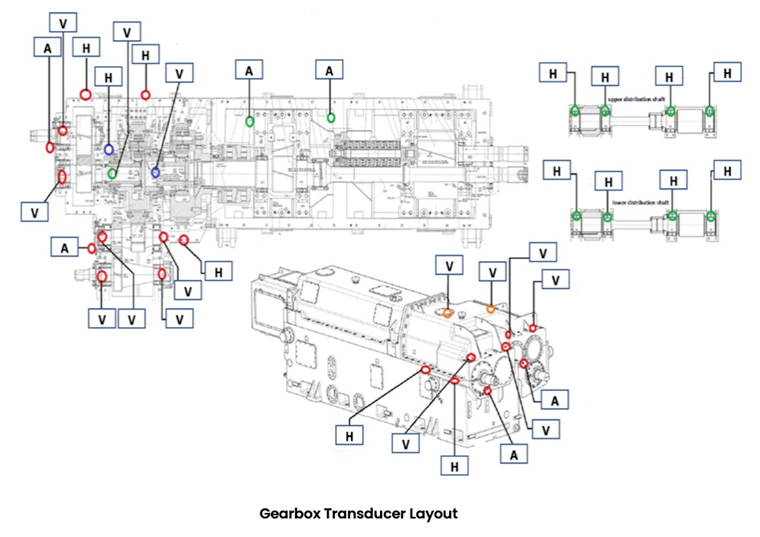

该挤出机变速箱是在下游行业运行的最大,最复杂的单套管变速箱之一。它是由巨大的14兆瓦主电动机和部署用于启动的额外的高扭矩可变速度驱动器(VSD)电动机驱动的。该机器在每个输出轴上提供320,000 nm(237,000 ft-lb)的扭矩,并包含60多个轴承,还有5个带27齿轮的齿轮耦合。

挤出机变速箱上的轴向移动过多,其主电动机导致其故障。在失败时,正在通过另一个条件监控公司的系统进行监控,该系统在失败之前没有提供保护或主动指示。更糟糕的是,它采用了非常低的采样率,这可能导致其无法检测高振幅轴向振动。

The Bently Nevada team proposed a solution, which included the industry-leading online monitoring system, ADAPT 3701/40 with S1 Evo, along with 40 vibration sensors that were installed across the entire extruder train. The Bently Nevada online monitoring system includes advanced signal processing as well as trends of the bearing fault frequencies. During subsequent operation, these capabilities helped to quickly and accurately identify the root cause of the previous failure. The System 1 pre-configured software alarm set points detected the high axial vibration problem early, preventing more severe damage.

The value realized from the system has prompted the company to pursue further improvements, including additional sensor locations to the main gearbox and main input and output shafts for axial thrust, incorporating the pelletizer gearbox into the monitoring system, integrating System 1 data with the DCS (Distributed Control System), and integrating OPC data for torque, lube oil temperature and pressure, motor current, and load.

System 1’s complex gearbox diagnostic and fault detection capabilities are the culmination of Bently Nevada’s years of machinery experience. The SER algorithm developed specifically for gearbox applications is an example of our constant condition monitoring improvements based on user feedback. System 1 Evolution’s comprehensive package of best-in-class connectivity, analytics and visualization capabilities create the most powerful, efficient, and effective condition monitoring software solution for any rotating or reciprocating asset in your facility.

内华达州贝利(Bellys Nevada)致力于在系统1中构建更多最先进的功能。从第18.2版开始,内华达州巩固了Adapt的风力涡轮机监视功能。Wind.wind.wind.west.wongeworts System 1 Evolution,将连通性添加到3701/60,3701/60,3701/60A和60m100风能监控产品,并为风力涡轮机操作员扩大条件监控平台功能。内华达州贝利(Berlys Nevada)通过开发用于齿轮网格故障检测的新算法,继续改善变速箱分析功能。正在考虑的未来可视化功能包括包装波形图,可用于视觉识别齿轮故障的位置。当今年晚些时候重新引入决策支持时,用户将能够创建自己的自定义规则来满足其资产和流程的个人需求。加入我们的旅程!

- epicyclic齿轮(2020)Wikipedia。可用网址:https://en.wikipedia.org/wiki/Epicyclic_gearing(访问:2020年5月13日)。

- McFadden,P.D。和Smith,J.D。(1985)。关于环境齿轮振动中牙齿网格的不对称性的解释,Proceedings of the Institution of Mechanical Engineers Volume 199 No. C1.Pages 65-70.

- Hanna,J.,Hatch,C.,Kalb,M.,Weiss,A.,Luo,H。(2012年)。使用边带能量比检测风力涡轮机齿轮缺陷,Orbit Magazine,第23卷。内华达州明登:内华达有限责任公司

- 改编自适应3701保护巨大的复杂挤出机变速箱贝克·休斯公司(Baker Hughes Company)首席销售经理Al新利appi al-Hawaj先前在2018年12月发表。

Copyright 2020 Baker Hughes Company. All rights reserved. Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not make any representation as to the accuracy or completeness of the information and makes no warranties of any kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect, consequential or special damages, claims for lost profits, or third party claims arising from the use of the information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation. Contact your Baker Hughes representative for the most current information. The Baker Hughes logo, the Bently Nevada logo, and System 1 are trademarks of Baker Hughes Company.