惊人的快速MDS远程响应使用系统1 20.1在阿根廷

Industry:Pulp and Paper

Application:在房屋发电

Solution:Remote Diagnostic Services - System 1 20.1

The Latin America MDS team was contacted on a Friday night, seeking for immediate support in getting the main steam turbine generator TG2 back online. After a non-vibration-related trip, the customer (Papel Misionero, ARCOR GROUP) had not been able to start the unit, due to a trip event on high vibration at turbine bearings near nominal speed.

On Thursday July 9th a short circuit in the 4MW-motor driving the high-density refining unit caused an electrical protection trip on unit TG2. During the process of bringing back online other areas of the plant, the auxiliary power unit TG 1 also tripped, causing the turning gear system on TG2 to shutdown, which had been operating for only two hours. After having solved the short circuit issue, the turning gear system on TG2 is turned on Friday July 10th, and the steam turbine generator is ready to start at 21hs that day. However, the unit tripped on high vibration at turbine non-drive end bearing when reaching 96% of full speed. After four unsuccessful startup attempts, Bently Nevada MDS Services was contacted at 11pm that night.

由于阿根廷的COVID19旅行限制(该工厂距离酒店1000公里),没有现场工程师甚至任何设备都无法到达现场。网站上唯一可用的硬件是现有的内华达州弯曲3500 protection system。考虑到对振动问题进行故障排除以及不利物流的紧迫性,只剩下一个选项。

在客户的IT部门的帮助下,安装了系统1 20.1并在连接到3500机架的笔记本电脑中远程许可。然后,笔记本电脑通过TeamViewer软件进行远程访问,到7月11日星期六下午4点,该单元准备再次启动,这次是与拉丁美洲MDS技术领导者实时查看System 1 20.1。

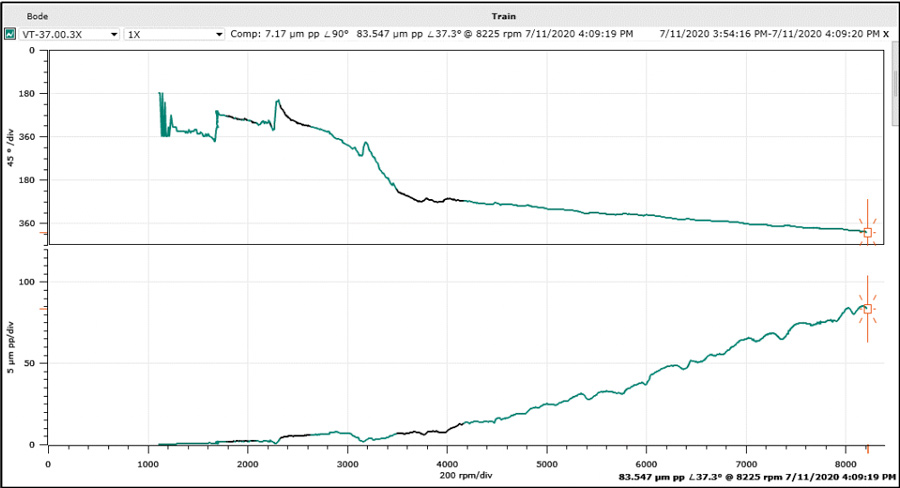

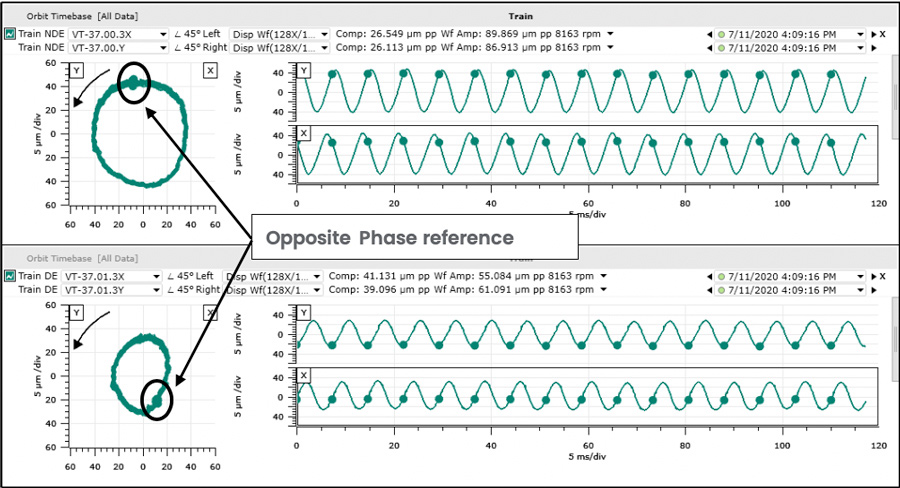

Plot # 1 shows a rapid increase in synchronous amplitudes above 5000 rpm on the turbine non-drive end bearing. Along with the increase in amplitude, direct orbits at both bearings presented a clearly circular shape, as shown on Plot # 2. Also, as indicated in Plot # 2, the phase reference or keyphasor dots at both orbits were located opposite each other, indicating second mode vibration.

即使这种行为似乎表明在第二种模式下剩余的不平衡升高,但这些症状表现出的条件使转子在转弯处运行时不可能发展出如此不平衡的状况(振动幅度在旅行事件之前显着降低了)。此外,由于缺乏转弯齿轮而导致的弓将导致第一种模式的高“相位”振动,但未观察到。

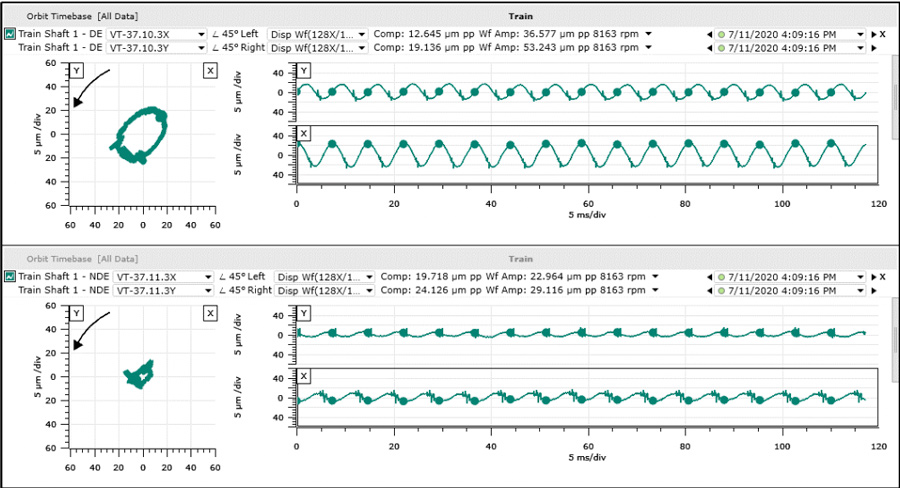

Given the relatively high synchronous amplitudes recorded also at the pinion drive end bearing (see plot # 3), the coupling between turbine and gearbox was believed to be related to the observed behavior.

That same day after the new trip, the coupling guard was removed, exposing a significant circumferential crack in the spool piece, shown in picture # 1. A preliminary analysis of the failure indicated that, during the two hours with no turning gear operation, the casing contraction during cooldown had applied excessive radial load on the coupling, intensive enough to initiate the crack or enable the propagation of an existing smaller one. The crack had induced a bow in this coupling component, which had affected the turbine rotor second mode response at speeds above 5000 rpm.

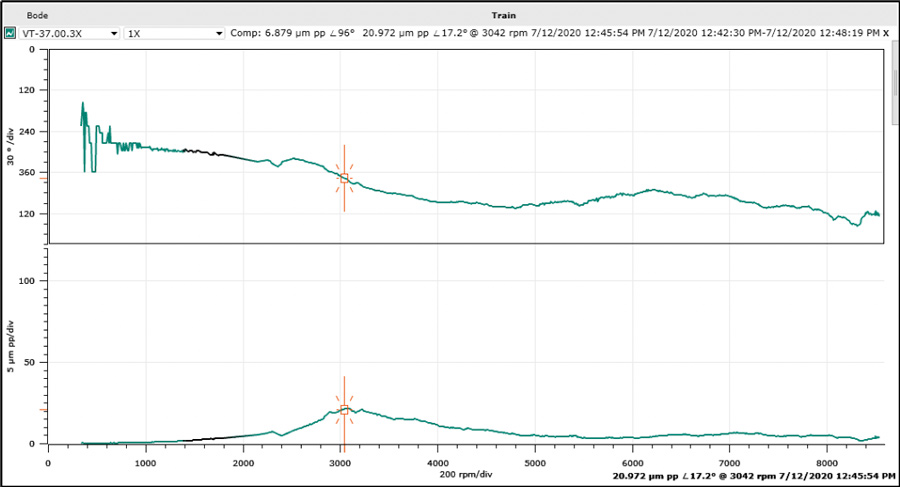

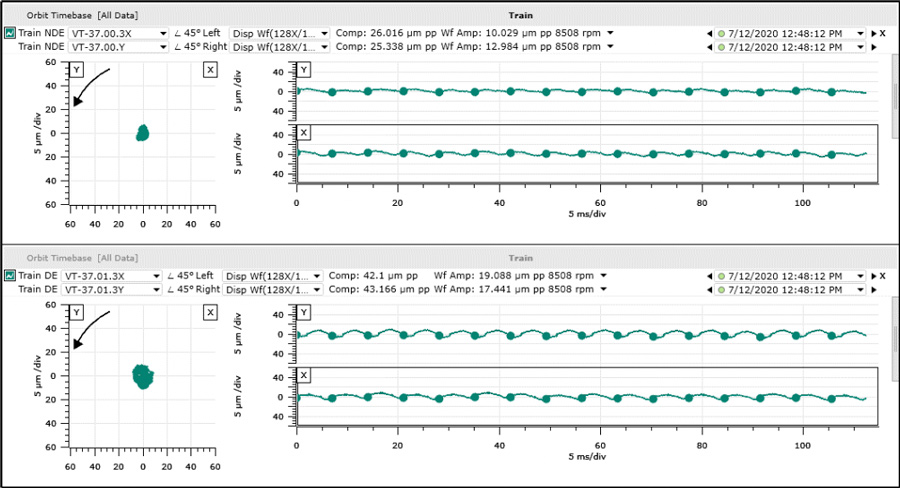

The damaged spool piece was replaced, and the unit was ready to start up on Sunday July 12nd at noon. Plot # 4 shows a smooth synchronous response in the whole speed range, with amplitudes below 25 µm pp (1 mil pp). Plot # 5 shows the compensated direct orbits for both turbine bearings once the unit reached full speed (8500 rpm). Once at full speed, load was gradually increased reaching normal demand by Monday 13th.

In a COVID19 environment where no field engineer or data acquisition equipment could be deployed on site, a combination of Machinery Diagnostics expertise and System 1 20.1, Bently’s latestAsset Condition Monitoring平台,启用了在记录时间内客户关键旋转设备中振动问题的远程故障排除。客户从不到一天的机械诊断数据中,从不到一天的机械诊断数据中,从不到一天的机械诊断来支持,从不知名的起源问题到解决根本原因并在两天内实现解决方案。