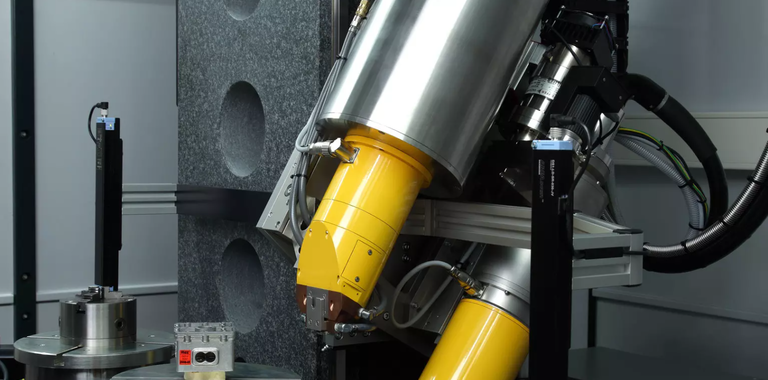

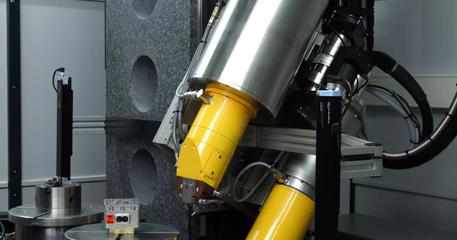

Phoenix V | Tome | X L 300

Phoenix V | Tome | X L 300是一种用纳米克特®3D计算机断层扫描(结构故障分析与计量学)和2D非破坏性X射线的选项检查。

The Phoenix V|tome|x L 300 system is equipped with a unipolar 300 kV/500 W microfocus source and optional nano CT capability in Dual|tube combination with a 180kV/20W high-power nanofocus X-ray tube for best detail detactability of 2.0µm.

CT-Scanner处理最多50公斤的大型样品,直径高达600毫米,精度非常高。该系统是一个很好的灵活解决方案,用于空隙和缺陷检测复合材料,铸件和精确零件,例如加性制造零件或涡轮叶片。它还允许高精度3D计量学符合VDI/VDE 2630-1.3。

强调

好处

独特的好处:

- 在样本量和密度的极限(直径为50 kg,直径最高为600毫米)的极限下进行微观和纳米扫描

- Great flexibility for 2D and 3D inspection on a wide application range

Features

凤凰v | tome | x L 300个功能是:

- 下一代的快速CT获取和出色的图像高度敏感的动态41探测器

- 领先的独家Waygate Technologies核心组件,例如X射线管,检测器,软件

- 获得专利的可选功能,例如高速通量|目标或分散|正确的技术

- - SD≤(6.8±l/100 mm)µm的领先测量精度,指VDI/VDE 2630-1.3,即系统性能的可靠重新验证

Applications

Highest precision micro- and nanoCT, e.g. for

- 中型光合金样品:铝,镁,锌

- Electronics: Complex/molded assemblies, sensors, actuators, battery cells and modules

- Complex assemblies (electrical/mechanical/medical)

- Structural inspection of 3D printed parts, composites, ceramics

- 逆向工程:金属,塑料,快速原型,生物力学

- 科学研究(植物,动物,地理和材料科学)

300 kV / 500 W微焦点X射线管 - 专门针对CT应用的优化,可选地与高功率结合180 kV / 20 W microfocus X射线管,可用于对较小和较低吸收的最高精度扫描

Waygate Technologies的独家专利Scatter|correct technology使您能够对高度辐射散射样品进行高度精确的CT扫描,并在锥束CT的吞吐量快的速度下,风扇束CT的优质图像质量。

Adaptive scatter correct filter offering unrivaled image quality by significantly reducing artifacts caused by reduced grey values in high absorbing sample CT datasets

以相同速度的双CT分辨率,或在与200 µm螺距DXR探测器相同的质量水平上双吞吐量。与16位检测器相比优化的14位技术offers the highest efficiency with a dynamic range of 10000:1 and thus saves time in use and also generates less noise in the image.

Improve efficiency with faster microCT scans or doubled resolution with higher power on a smaller focal spot

This easily removable holder allows automatic change of different samples

In combination with the Sample|changer, the optional Filter|changer allows to perform mixed batch CT scans

长达长期稳定性并通过长寿|丝(可选)来确保长期稳定性并优化系统效率(可选)的长期稳定性和优化系统效率(可选)

Scan longer parts with improved image quality to increase probability of detection (POD) with efficiency and ease.

Scan even larger parts with up to ~70% larger scanning volume.

定义虚拟扫描旋转轴,以便于扫描调整和柔性ROI CT扫描

The Multi|bhc tool corrects streaking artifacts which typically occur as multiple dark streaking bands positioned between dense areas in multi-material samples.

Maximize speed and accuracy and reduce your operational costs by implementing robot loading into your inspection procedures

The system guarantees a measurement accuracy of SD ≤ (6.8 ± L/100 mm) µm according to VDI/VDE 2630-1.3 for reliable revalidation of the system performance and reproducible measurement applications.

The Ruby|plate calibration phantom and the compensation of thermal drift effects based on the use of temperature sensors enable automated measurement sequences and precision to a new level of performance for even larger parts.

This enables the improved VDI 2630 compliant accuracy specification and three times faster performance verification of multiple positions - reliably and reproducibly:

- 名义上的CAD比较

- Dimensional measurements / wall thickness analysis

- Reverse Engineering / Tool Compensation

完全自动化您的数据获取,卷处理和评估

Waygate Technologies的全球工业X射线2D和3D CT扫描服务