Waygate Technologies制造了影像学测试(RT)和计算机断层扫描(CT)解决方案工业世界更容易进入,,,,一种llowing you to attain peace of mind while also leveraging the cost savings ofNon-Destructive Testing (NDT)。

当今可用的X射线检查和CT解决方案范围最广 - 来自移动设备conventional film,computed和数字田间X光摄影解决方案(CR&DR)至2D X射线检查系统和3D计算机断层扫描- 我们将X射线和CT检查和计量学带到了生产层,设计了最坚固,富有成效和可靠的X射线扫描解决方案等等。所有这些都可以帮助您节省时间和金钱,同时提供最安全,最可靠的产品。

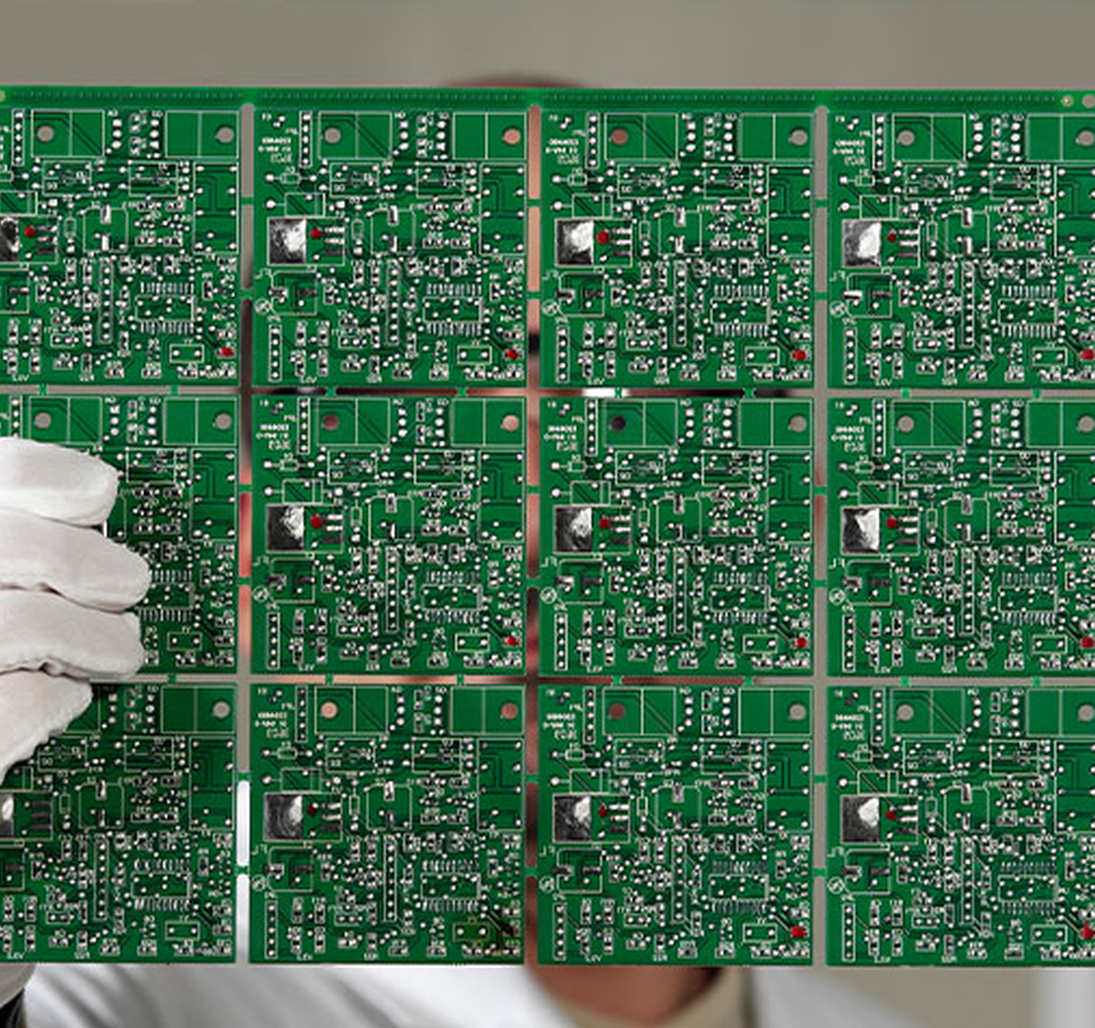

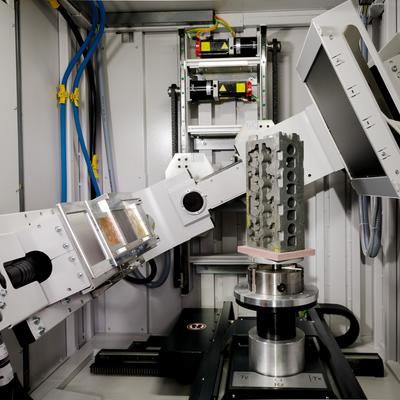

生产地板上的自动检查

Waygate技术’ powerful X-ray inspection and CT technologies aren’t just for lab environments anymore.

和support from our experienced team, we can help you integrate 2D and 3D inspections into your manufacturing processes快速揭示隐藏的缺陷,厚度的变化,组装偏差和其他看不见的组件。

降低错误,提高生产率,提高质量和节省时间。

NDT的解决方案

Even in the most demanding industries and environments, our多元化和全球范围的收藏移动和固定的工业射线照相检查解决方案可提供快速,可靠的结果。

Wherever your Non-Destructive Testing (NDT) needs take you:在实验室,生产地板甚至领域,,,,Waygate技术has a solution that will allow you to get the greatest degree of accuracy in the most efficient way possible.

和独特的创新,独家探测器技术和较短的曝光时间,您可以获得所需的准确检查结果highest levels of both safety and productivity.

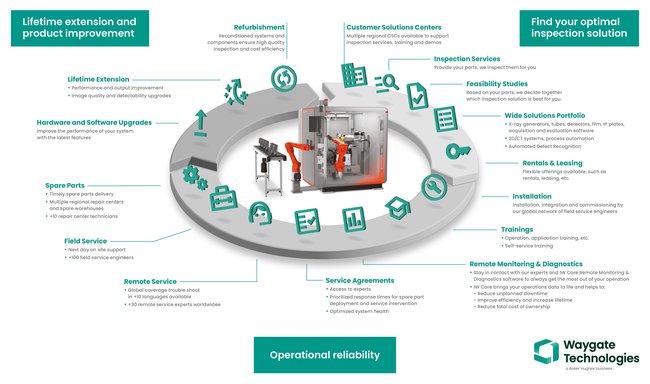

Lifetime Solution

Our service solutions provide state-of-the art support through the lifecycle of our equipment.

From installation to dismantling, our team provides both proactive and predictive services as well as long-term performance optimization to maximize the outcomes for your operation.

Inspections are a huge investment in a product. We’ve turned them into added value by helping optimize processes, maximize uptime, predict failures, and improve product design.

Industrial X-ray Tubes and Generators

Proven, powerful Seifert X-ray equipment including portable, mobile and stationary X-ray generators and tubes, which are designed for the最高的吞吐量,图像质量和寿命 - 持续和improve productivity in the field.

高X射线剂量和最短的曝光时间平均检验率更高的生产率和较低的运营成本,同时为您提供most accurate results possible。

影像学测试(RT)/X-ray Inspection落在non-destructive testing (NDT)并且是一种通过用X射线渗透目标样品的方法,并因此在材料密度上进行突出显示偏高,该材料密度可以指示需要解决的不完美。

X射线照相使用X射线和伽马射线to produce a radiographic image of the target sample, allowing the technician to observe any changes in material thickness, internal and surface defects, and even assembly details (i.e. welds, joints, connectors) to ensure the highest levels of quality and safety in your production.

的关键好处之一影像学测试(RT)是为给定目标样品生成了扫描的永久性,硬拷贝(在X射线膜的示例中)。在数字传感器/检测器的示例中,该记录是可以在本地或远程存储的数字记录,并且不需要与X射线膜相关的处理和存储需求。

什么是X射线?

X射线是A。电磁辐射的高能形式with a wavelength in the range of 1nm to 1 pms, approximately 1000 to 1,000,000 times smaller than the wavelength of light. Due to their being highly energetic,X射线是A。ble to pass through materials that absorb ordinary visible light.

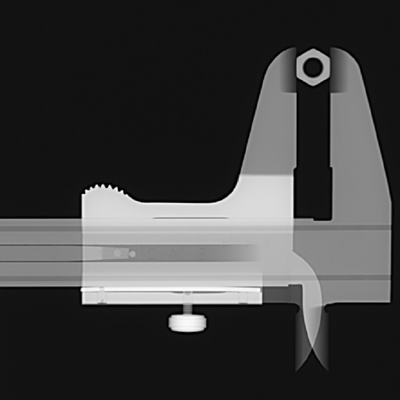

通常,X射线检查系统由辐射安全外壳组成,辐射保护柜,包含线性对准,X射线管和X射线检测器。一个可远程控制的操纵单元允许用户将样品定位在光束中。The final X-ray image is displayed on a monitor for computerized image processing. In addition,X射线系统可以配备具有电子程序控制,以允许自动样品检查。The X-ray image shows object features based on differences in material density.

通过对象时,X射线光谱的一部分被吸收。物体的密度较厚或更高,X射线越多,不会通过。Those X-rays that pass through the object strike a detector where an X-ray image is created.该图像由不同的灰色阴影组成,具体取决于事件射线的强度:厚度较厚或密度较高的材料(例如铁,铜和铅)的部分比塑料,纸甚至空气等密度较少的材料看起来还黑。

这个然后在黑暗的房间里处理电影- 就像典型的摄影胶片一样 - 胶片捕获的各种辐射程度表示为白色和黑色的不同值。目标样品未吸收的X射线将导致射线照相检测器暴露。These areas will appear dark. Areas由于吸收更高或更致密的材料,吸收了更高的水平会显得轻巧。

这样,目标样本的区域通过磨损,孔隙率,裂缝或未对准等瑕疵而改变的区域将出现为黑线making it easier for a skilled technician to detect。

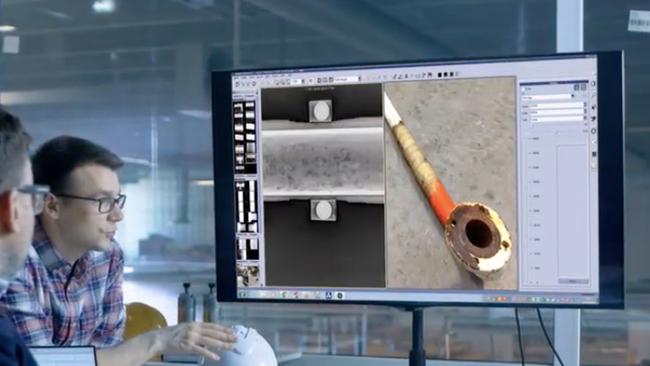

影像学测试(RT)主要用于testing and grading of welds在管道上,压力容器,存储容器,管道和结构焊缝上。

真的任何与焊接一起融合在一起的任何东西都可以承受某种压力或负载进行射线照相测试,以确保焊缝的完整性。

Other tested objects includemachined parts, plate metal, or pipe walls(尤其是关注腐蚀的地方)。

陶瓷,,,,light metal castings, or additive parts such一种s those used in the航空航天和汽车行业也通过射线照相进行测试。

影像学测试(RT)可以通过X-rays或者gamma rays。X-rays are produced via an X-ray tube, while gamma rays are produced by the introduction of a radioactive isotope.

These radiation sourcesuse much higher energy levels than those associated with electromagnetic waves。

由于射线照相测试涉及电离辐射,这是重要的是要确保对适当的安全准则进行传达和遵守,以防止暴露。

影像学测试(RT)优惠several benefits over other forms of NDT.Some of those benefits are:

- 一种record of the scanthat can live either on film or digitally

- 一种bility to浏览整个样本

- 一种较高的身份证缺陷

- 一种操作员和检查员需要较低的技能

A well-trained radiographer can not only一种ccurately locate a defect使用RT,但可以还标识其类型,大小和位置。

当涉及缺点时,显而易见的事实是you are dealing with relatively dangerous materialsthat can cause adverse, long-term health effects when exposed to radiation.

Additionally, traditional RT solutions, especially film-based ones, require大量的时间才能产生可用的图像,,,,thus elongating your production cycle.

这就是为什么当今这么多组织是拥抱数字探测器,避开了与传统X射线胶片相关的处理时间。

X射线发电机

X射线发电机通过电子发射产生X射线in a vacuum。达到目标材料后,X-rays are emitted and directed towards your target sample. In the sample, the x-rays are absorbed or scattered according to the target's material and density. After having passed through your target sample,然后由检测器捕获光子,例如X射线膜或数字探测器。

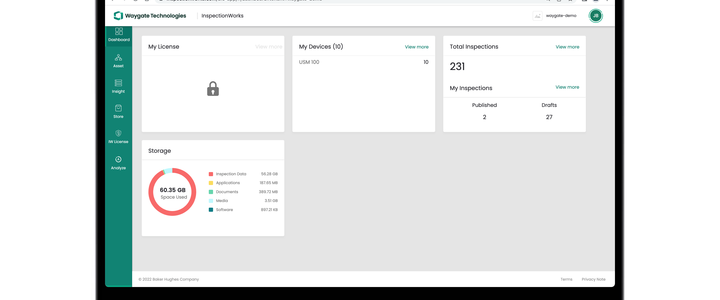

Digital Conversion

Many organizations today aremoving away from traditional film-based radiography to a digital sensor-based solutionin an effort to save time, reduce costs, and improve overall NDT performance.

超声测试(UT)和Eddy Current Testing (ECT)由于信号质量的增强,灵活的探测选项以及它们不涉及辐射或危险化学物质,因此今天NDT的两种领先方法。

UT依靠ultrasonic waves to probe through your target sample并检测到其中的任何偏差,同时使用ECT电子电流在您的目标样本中运行thus generating magnetic fields which highlight material density and thickness deviations.

ECT和UT(尤其是分阶段阵列超声测试)都是比RT安全得多,在某些应用中可能会减少耗时。

Portability它们也是ECT和UT解决方案的标志,因为它们往往较小且易于操作,因此将自己用于现场使用,而RT则更多地用于实验室或生产线应用。话虽如此,there are several portable RT solutions todaythat can be deployed into the field with success.

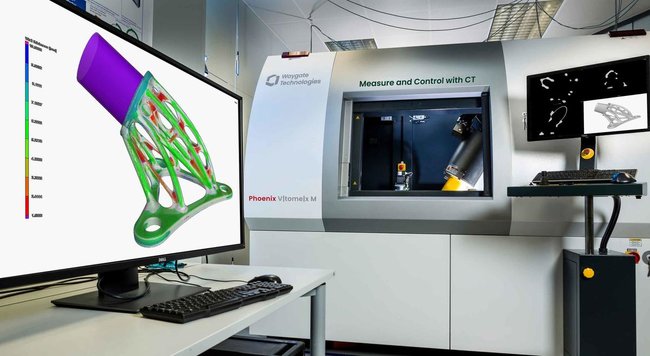

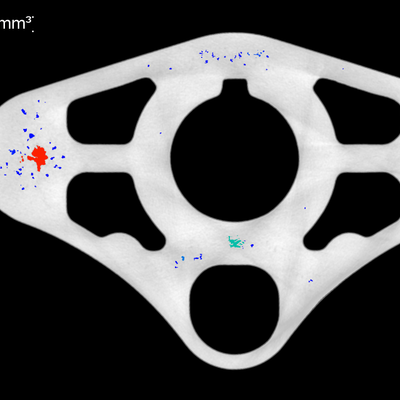

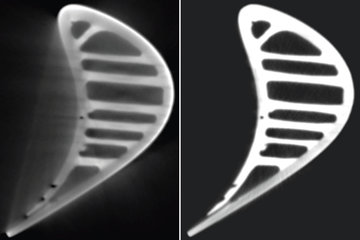

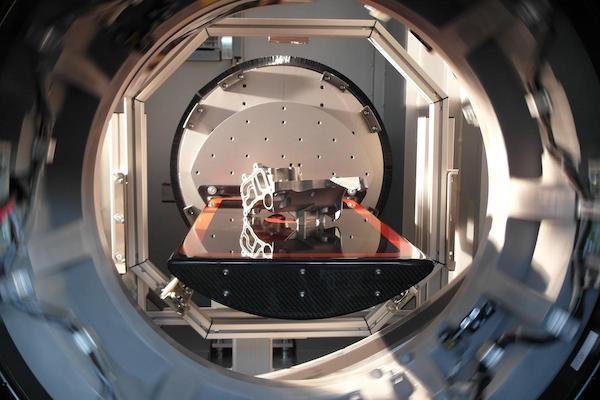

CT检查提供三维的空间图像of the object under inspection which can be virtually sliced in any direction. The CT-image shows different materials or density deviations (e.g. porosity) as不同的灰色阴影(或不同的颜色)。

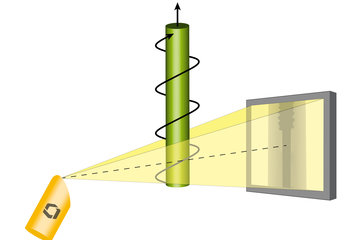

为了生成三维图像,围绕单个旋转轴(360°)拍摄了大量二维X射线图像(或切片)。这些X射线图像是重建为结构的体积表示(3D)使用复杂的重建算法。

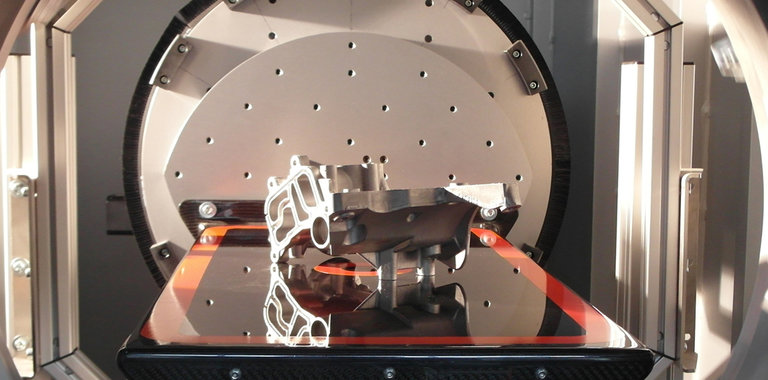

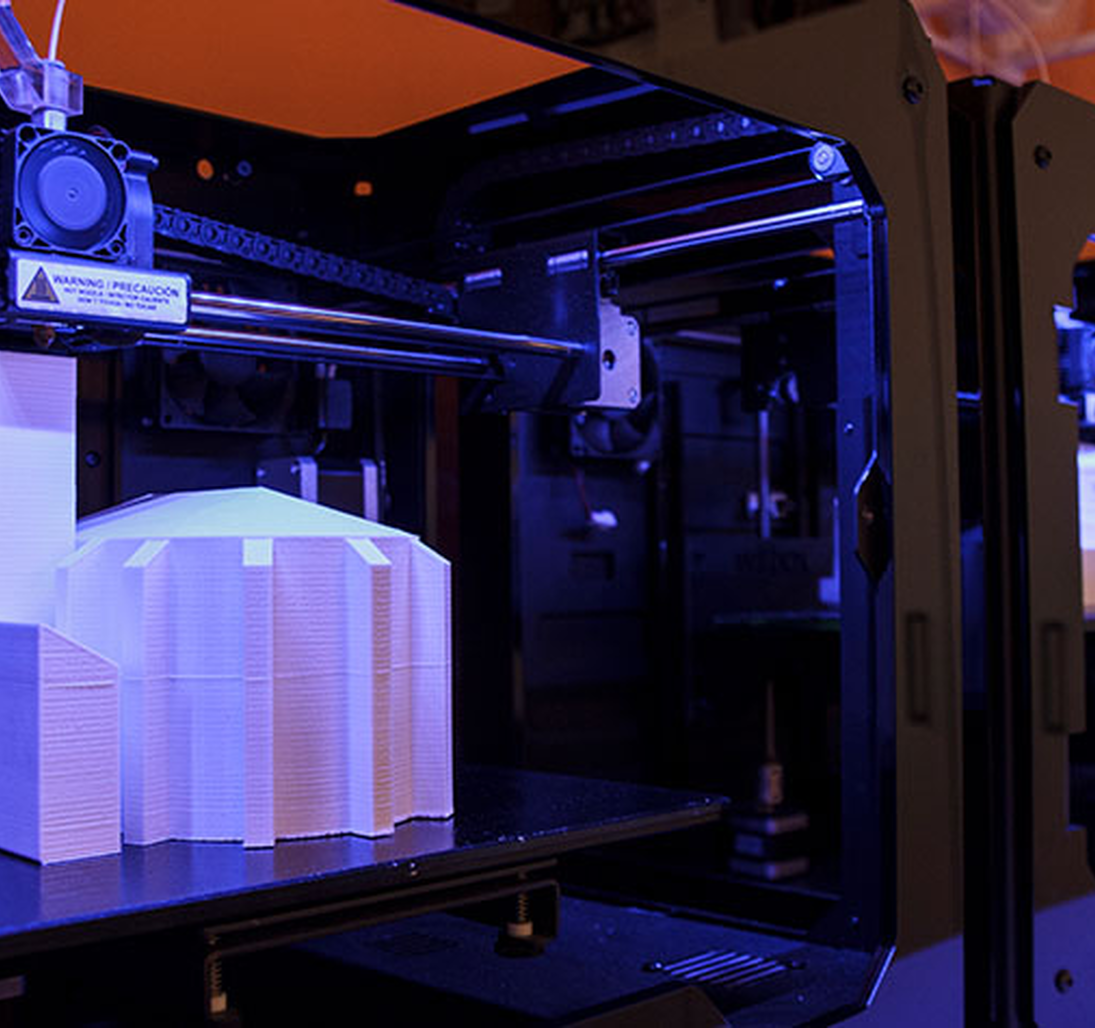

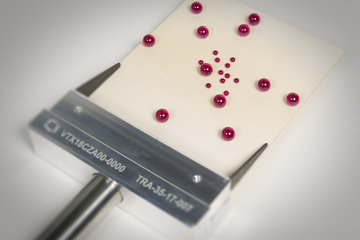

添加剂和复合零件检查与计量学

Waygate技术优惠一种wide range of large and small CT systems that can accelerate your rate of inspection of additive and composite parts, as well as, inspection of small batch prototypes and light metal castings. Automotive manufacturers are turning to our Phoenix | X-Ray CT solutions, providing high throughput at high inspection quality levels.

Waygate Technologies提供广泛的产品和服务,以提高效率和安全性

From weld inspections, gas turbine inspections, pipeline inspections, to Predictive Corrosion Management (PCM) solutions, leveraging multiple products within our portfolio Waygate Technologies provides oil and petrochemical companies around the world the necessary tools to maintain optimal performance levels in their plant and offshore assets.