强调

好处

- 能够从15米之外感知电线断裂

- 检测辅助设备下的卸载的拉伸线

- 对寿命延长计划的贡献

Features

- Provision of integrity assurance

- 临终场景的管理

- High frequency data collection providing analysis assurance

申请

- 安装到外鞘上

- ROV,潜水员或顶部可部署

- 适用于所有制造商的灵活立管

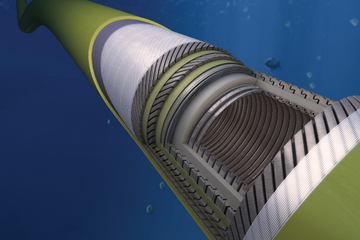

结构完整性检查和监测系统,用于保护灵活的立管

MAPS®is the industries premium technology for the management of flexible risers from all manufacturers. The technology is a non-destructive, non-contacting technique for measuring stress within the steel armor wires with a unique capability to assess the integrity of the primary load-bearing elements within the pipe design. MAPS® is available as an inspection service or an installed monitoring system with continuous data collection.

新的完整性评估水平

Conventional inspection technologies require the exact defect location and equipment must be positioned over the affected area. Critical pipe locations are often difficult to reach because they are subsea or ancillary equipment can prevent access. MAPS® technology can identify a wire defect including breakages from 15 metres away, including assessing integrity in and near the splash zone and up to the top termination, where there may be no access to the pipe. Scanners can be used above or below sea level which are installed by rope access, diver or ROV.

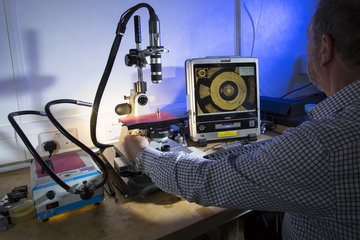

Engineering Principle

MAPS®技术检测到钻孔压力发生变化时,弹性立管的钢盔甲电线内的施加应力变化。如果电线在压力变化下没有显示出施加的应力的变化,则电线被视为非负载轴承,这表明电线已遭受疲劳损伤。它是使用电磁应力测量系统测量的,该系统使用铁素体钢的基本物理特性进行操作,因为磁性特性对机械应力敏感。检查系统通过弹性外护套磁性地与钢盔甲层融化,该鞘不需要在立管制造阶段加入传感器或特殊组件。