强调

好处

- 高可靠性和低振动水平

- 冷凝器冷却高效

- 轻巧和紧凑的设计简化了安装,并提高了维护的易用性

特征

- 模块化设计为量身定制的解决方案提供了灵活性

- 海水应用的复式材料

- 标准:ISO,他的(设计);EN,ASTM(材料);ISO(性能)

申请

- 水转移,灌溉,淡化,废水

- 联合循环发电厂

- 石油和天然气,液化天然气(海水和消防系统),化学物质

概述

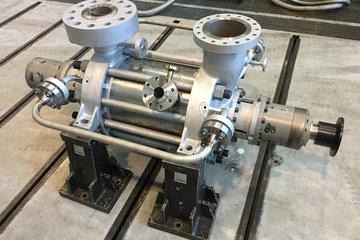

由GE Steam Power许可的Saturne™泵是垂直涡轮泵(或悬挂碗泵),可用于带垂直水柱的湿坑。它是由直接电动机或通过变速箱驱动的,该变速箱安装在泵头或单独的地板上。它设计用于最多20平方米/s的大流量,这有助于大量的灌溉目的或大型海水淡化厂的摄入量。目前,全球有500多个Saturne™泵,它们以高可靠性和低振动而闻名,且不到1.8 mm/s。

该泵由带有轴向,混合流或离心叶轮的高效液压模块组成。浸入泵液或独立冲洗系统中的轴线;和制造的套管,其中包括排放柱和肘部。

投资组合包括各种类型

- 焊接或铸造组件

- 碳钢,不锈钢,双链钢或超双链

- 拉出或非淘汰

- 指南轴承的几种技术:橡胶,石墨,陶瓷

海水应用材料

- 叶轮:双工或超级双工不锈钢

- 泵外壳:双工或超级双工不锈钢

- 圆柱和送货头:双工不锈钢

- 轴:双链不锈钢

生和淡水的材料

- 叶轮:不锈钢

- 泵外壳:铸铁或碳钢

- 圆柱和送货头:碳钢

- 轴:不锈钢或马丁西钢

规格

模型

最大限度。流速(M3/H)

最大限度。头(M)

最大限度。电力(KW)

星期六40-700

2,000

80

550

星期六80-550

4,000

45

620

星期六60-850

7,000

50

1,100

星期六60-1500

24,000

40

3,000

星期六80-1400

35,000

20

2,200

星期六125-1600

60,000

12

2,300

星期六200-1700

65,000

8

1,600

星期六315-1900

70,000

5

1,100