在一个多世纪以来,currently, steel pipelines. Meet the latest industry disruptor: composite flexible pipe. This next generation of non-metallic pipe is a proven alternative for a fast-growing range of applications.

What is non-metallic pipe and what makes it different? Lightweight and flexible, reinforced thermoplastic pipe can optimize the core structure of flowline and pipeline networks and economically support the transport of CO2为了存储,氢的运动或现有基础设施的转化以携带这些气体,这对于行业的能源过渡和脱碳至关重要。

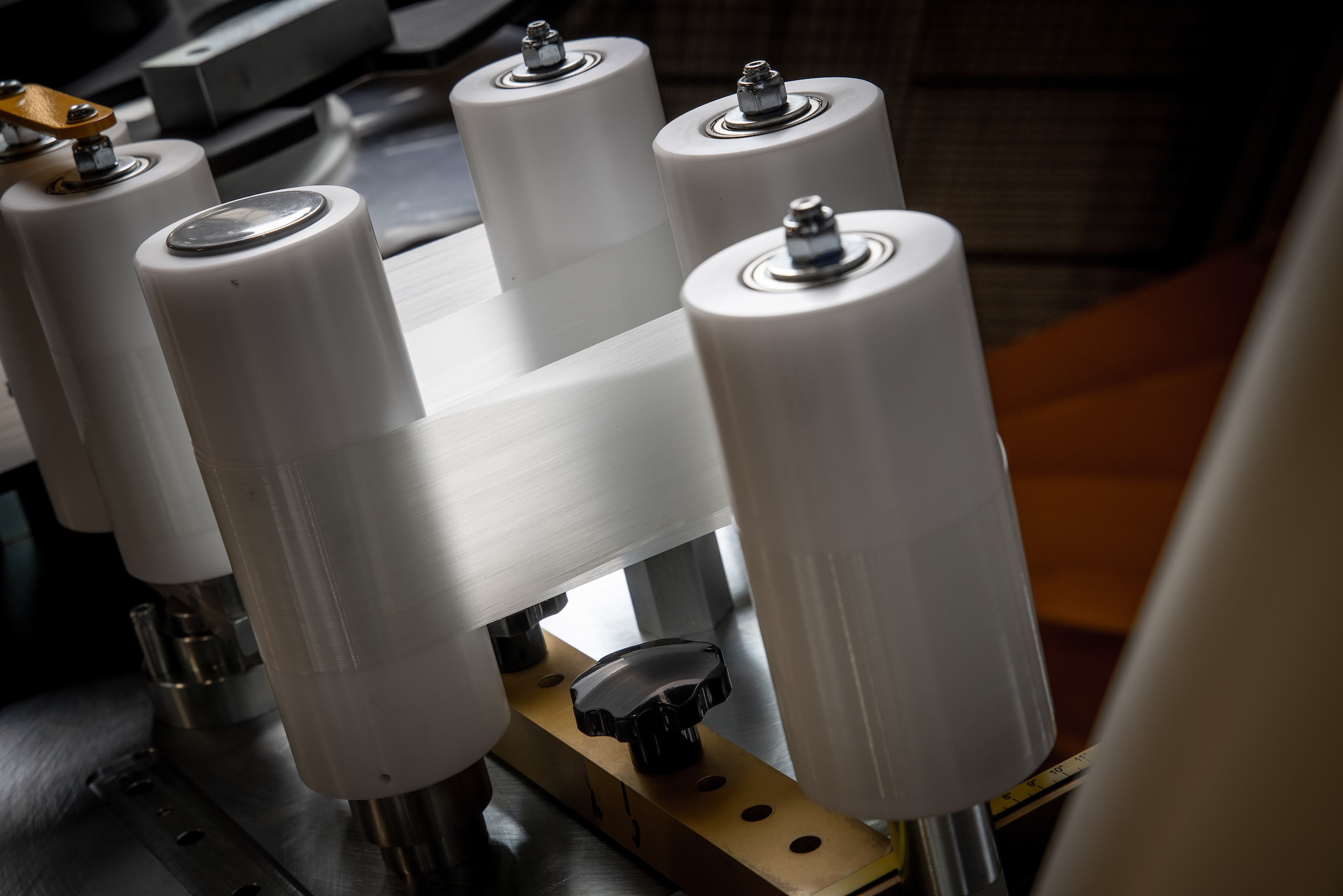

At Baker Hughes, we’re manufacturing下一代陆上灵活的管道在我们在休斯敦的最先进的设施中。s哦,在这里,我们探索了其中的七个超级大国非金属陆上管道:

1.灵活

Let’s start with the inherent flexibility of the product, which brings benefits both as it is installed, and as it is operating.

该管道是一个非常容易进入沟渠的产品:您可以举起它,可以弯曲它。如果您想用钢管来做到这一点,则需要三到四个侧臂和一个大型推土机来启动。这意义重大安全曝光,因为钢具有刚性和重量,因此当您使用用钢制成的任何东西时,它是一个额外的开销。

当管道使用时,灵活性(或合规性)同样重要。并非所有运营商都需要放置管道的土地都是整洁,紧凑的。您可能需要穿越各种地球危,例如滑坡,泥土和沼泽。这给钢管带来了很大的风险并克服了它,传统上,操作员依靠前方依靠大量的额外设计工作和增加的结构容量,例如扩展循环(基本上是大型的U型U-Bends中的大型U型)或弱连接的弱环节阀。管道操作员始终努力避免石油或天然气甚至盐水溢出,因此承担责任负担很大,并且操作员必须在其钢管管道系统中具有额外的灵活性。复合线管的水平不相同风险是因为它具有灵活性,并且可以轻松地结合弯曲和环,从而有助于任何地面运动 - 只需使用其自然依从性即可。

2.健壮

strength is relative and people confuse strength with rigidity. It is perhaps best to talk about a product having ‘deep robustness’. The reason for the remarkable shift to composite materials in the past 20 years is that they can be very, very robust. Let’s take aircraft structures as an example. They are not being used just in bulkheads and seats; the wings and load-bearing components are now made from both metallic and non-metallic composites. When something hits it at high speed, such as bird strike, a composite absorbs way more energy than a solid or dense material.

在管道的工作环境中,有高冲击载荷,加热和冷却周期和压力循环,具有高延展性的材料可能比刚性的材料更可靠。

这些管道是为极端事件设计的,然后将安全因子添加到顶部,以便它们适合给定的职责,但是它们可以超越这些设计参数,而在短时间内我们称之为“沮丧的条件”。必须内置足够的安全余地,以允许那些不可预见的事件,这可能会测试管道一生的稳健性。

3.连接

非金属管既连接又可连接。

传统上,应将应变量规,电子传感器和光纤传感器安装在钢管中以进行特定应用,通常是条件监测。但这意味着将钢与结构外部的钢粘合在一起,甚至可能在绝缘涂层外部。然后,操作员完全依靠粘结和光纤传感器或电量规来维护其寿命并得出正在发生的事情里面来自外部。

灵活复合管的超级大国是光纤可以嵌入在the structure itself, as they are compatible with the reinforcement material used。OPaltic-Fiber监视是一种用于条件监控和完整性评估的通用工具。标准电信-等级纤维与其他纤维嵌入结构中,并成为管道的整体部分。

在用嵌入式光纤运行20英里的管道上,我们可以沿着整个距离测量各种物体(例如分布温度)。例如,使用光纤管道监视,如果内部外部或外部有泄漏,则将显示在监视软件上的温度差。然后,我们可以调查该特定位置,而无需挖几英里的管道。

One capability that is most interesting is the use of optical fibers for vibration monitoring. With an I/O box (input/output) at one end and a reflector at the other, we can interrogate the line signal backwards and forwards. When monitoring the fiber acoustically, vibrations will be detected if for example somebody’s digging in the vicinity. This means in advance of somebody digging a hole near and potentially ‘interacting’ with the pipe, the operator will get a warning. The value of that alarm capability for operators is obvious.

不太明显的是,操作员有监管义务积极确认管道状况,包括持有压力,没有显示出降级的迹象,并且仍然适合目的。这些板载监控系统允许操作员进行这些检查,而无需内部使用智能猪或外部进行内部检查线路。运营数字化迈出的一步。

4.安全

运营商和服务公司都致力于安全作为不可商服的安全,并共同努力,以最大程度地减少发生的事情的可能性,并减轻任何不利后果。在能源领域,移动重量的机械或设备是最危险的活动之一,人们有受伤的最大风险。

复合柔性管在这里带来了非常简单的超级力量 - 它比钢管轻,并且适合卷轴。

这种基本特征降低了受伤的概率和后果。我们在一辆卡车上有一把非常轻巧的管道,而不是许多重量的钢管装载到一辆站点上的20-30辆卡车上。因此,从统计学上讲,这立即减少了发生道路事故的暴露,并减少了与移动的钢管接头和卡车上移动的钢管接头相关的举重和降低危险。

钢管道的安装涉及焊接,弯曲,侧臂和许多重量的设备。复合柔性管安装的需要更少。反铲将打开沟渠,要么是反铲或几个人可以手动将管道抬到沟渠中,还有100个可以在不中断连接器或焊接的情况下铺设米米的弹性。减少的关节数量还降低了水交操作期间泄漏的风险。

In short, the whole construction operation is substantially de-risked: far fewer people, a lot less equipment, and the operations are much simplified.

此外,由于腐蚀而导致的壁厚损失的操作风险,这是一个关键事实或者钢-pipe failure, is non-existent in a non-metallic onshore pipeline.

5.清洁剂

The composite pipes are fully recyclable at the end of life and are as simple to replace or remove as they were to install. During installation there is at least 30% less land required for the right-of-way, when dealing with many fewer vehicle movements – this has an environmental benefit as well as improving the owner/operator’s return on investment. Of course, many fewer vehicles for transportation and installation also means lower emissions.

由于复合管的内部非常平滑,因此这意味着较小的直径管可以实现更好的流体运输流量,从而再次影响效率,项目成本和环境足迹。

6.预算

The project manager is responsible for the budget and their first question is, ‘How much am I spending upfront?’ With non-metallic pipes, the discussion moves from comparing equipment unit costs, which is what the industry normally focuses on, to look instead at total installed cost. When we take the cost of our pipe, the cost of installation, and the cost of the operation, we can demonstrate that in most applications, this pipe is significantly – 20-30% and sometimes more – lower than the installed cost of the equivalent steel pipe.

在查看OPEX时,操作员可以从隐藏的成本优势中受益:无需将化学物质注入管道以防止腐蚀,这可能是昂贵的。氧气清除剂和蜡堆积也不是问题,它消除了常规的智能烟熏操作。同样,不需要外部腐蚀(需要阴极保护系统安装和终身维护)。考虑所有这些“传统”管道维护项目大大减少s管道在其生命周期中的运营成本。

7. Advanced

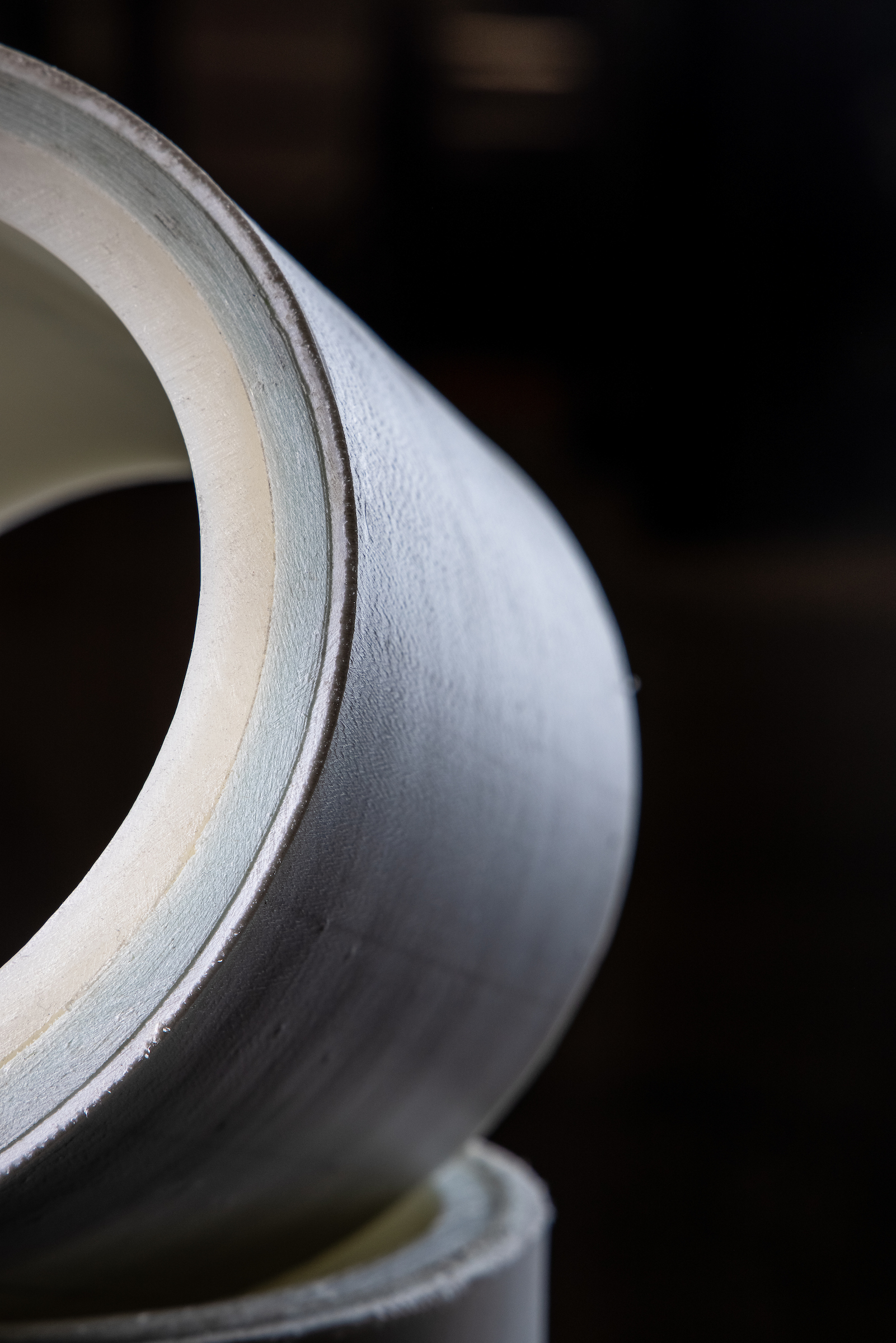

C复合管是一个很好的例子通过先进的配置和制造业。我们从一个可以快速更改的组件菜单中工作。我们使用相同的机器,在某些情况下是相同的根据材料 - 复合纤维磁带和聚合物。If运营职责需要它,我们可以代替管道内的高温聚合物或不可渗透的聚合物,并使其他所有东西保持不变。

与增材制造一样,用于生产这些管道的技术意味着每个结构都可以根据应用的需求进行优化。我们的制造能力可以制造任何直径的管道,通过施加或更少或更少的层,增加或减去刚度,增加温度容量等,以完善压力等级,以适合其应用。

钢管已建造为API标准,因此操作员将获得四英寸的管道,六英寸管道或八英寸管道,除了壁厚(管道时间表)之外,它们之间几乎没有区别。抵抗压力所需的实际钢量相对较小,但是标准要求添加其他材料以应对弯曲载荷以及额外的安全性和腐蚀津贴,并在标准的钢管设计中具有很大的冗余。

复合材料也是一个非常快速的制造过程 - 如果需要,可以在几天之内生产一条柔性管道。为了获得指定的等级,可能需要提前几个月从工厂订购钢管接头,而我们可以在几天内从相同的基本原材料中构建各种产品。

能源前进的故事

注册以保持最新的最新创新和塑造我们行业未来的人们。