强调

强调

提高效率

简化和简化分布式光纤温度感应,分布式应变敏感性和分布式声学传感数据的管理。

- 以网格形式,趋势图或热图查看数据

- Configure alerts for key events or to prompt action

- 自定义井下分析

减少开支

通过灵活的,基于Web的域AS-AS-Service解决方案无缝传输,存储和可视化关键井数据。

- 减少工作量

- Reduce operating costs

- 选择灵活的部署模型

增强产量

利用先进的可视化来快速识别趋势,诊断井下状况并改善恢复。

- 创建关键数据类型的集成可视化

- Track temperature, strain, and acoustic readings

- 组合DTS,DSS和DAS数据

Combining fiber-optic distributed sensing data with other surface and downhole information can generate the insights you need to make more informed operational decisions—and enhance production and recovery. But practices for managing this information are complex, costly, and time consuming, making it difficult to extract the full value of your data.

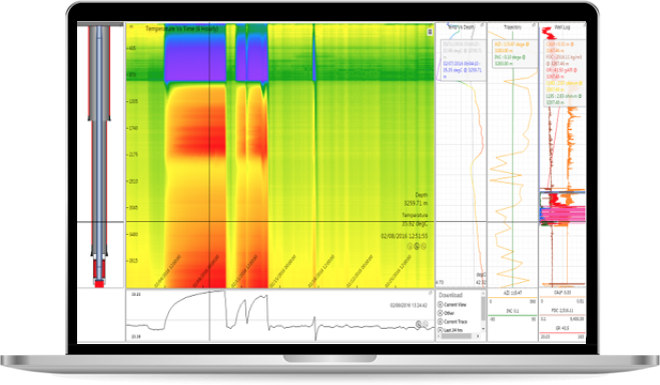

我们的ProductionLink™光学解决方案服务加快并简化了光纤分布式传感数据的管理。灵活的,基于Web的解决方案无缝传输,存储和可视化分布式温度感应(DTS),分布式应变感应(DSS)和分布式声学感应(DAS)数据,可以随时进行即时访问和快速分析或位置。

此外,软件即服务(SAAS)部署模型可降低您的工作量和成本,并消除过多的硬件,软件和许可证。

An interactive, web-based dashboard tracks temperature, strain, and acoustic readings in each asset, across both time and depth. It also enables you to combine DTS, DSS, and DAS data with other surface and downhole information, including well logs, schematics, and trajectories. Through integrated visualizations of these different data types, you can rapidly identify trends, patterns, and anomalies to diagnose downhole conditions, enhance production, and improve overall recovery.

生产标记语言标准的使用简化了井数据的管理和集成,因此您可以快速,轻松地共享数据,跟踪元数据并保存多个版本,而不会在此过程中丢失任何原始数据。

You’ll also get instant access to complete data sets along the entire wellbore, thanks to the service’s ability to transmit and store high volumes of data in real time. In addition, its scalability means users can track the performance of multiple fields or a few select wells.