强调

强调

好处

- 评估单次成功和缓解建议的风险

- Optimizes milling parameters determined from data analytics models

- Optimizes in real-time for complete control of downhole milling conditions

Applications

- Casing Exits

概述

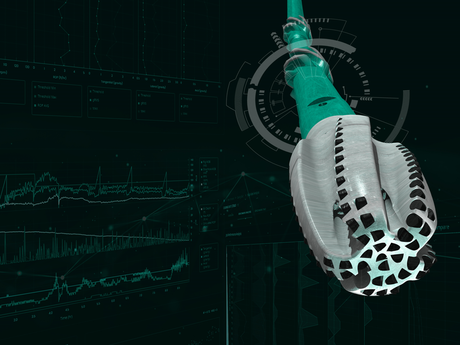

通过减少窗口阻力,减少振动减少,并增加ROP,以确保单次窗口铣削,以便更快的窗户铣削和更高质量的窗户使用xSight analytics service for casing exits来自贝克休新利app斯。Xsight利用良好的数据分析和启用基于云的软件应用程序来通过提高操作效率和一致的服务交付来增加价值。

壳体出口操作提供了一种从现有井眼中访问储层区域的方法。但是,在一次旅行中铣削干净的外壳窗口并不能有效地实现。在更复杂的海上井中,由于井下设备的故障或次优窗口质量引起的额外旅行,故障率可能高达20%,这需要额外的窗户抛光。非最佳铣削参数可能导致过度振动和其他井下铣削功能障碍 - 降低铣削效率,在最坏的情况下,导致井下工具失败。

Xsight服务收集了良好的数据,以进行风险评估,并根据数据分析模型提供推荐的铣削参数,这些模型已从历史数据集中培训,并通过该领域的绩效提高验证。来自历史工作的数据集用于开发预测性和规范性模型。通过这种方式,细节,BHA详细信息,井下数据和表面数据为您的外壳出口操作提供了整体视角。准确的井下测量结果消除了不确定性,并为分析建模提供可靠的输入数据。

During operations, advanced analytics are used with real-time downhole measurements to enable data-driven decision making. Prescriptive analytics, coupled with real-time downhole measurements, ensure the best operating envelope while enforcing accurate control, combined with a corrective action roadmap during milling. This approach helps you optimize rotational speed (RPM), weight on bit (WOB) control, torque-on-bit (TOB), vibration, ROP, and window quality.

工作后,从钻机和井下工具收集数据以启用职位分析。这包括关键绩效指标(KPI)和数据可视化,以描述工作绩效并提供未来的建议,从而实现实时优化和持续改进。

Contact us to learn how the xSight service can help you assess your next well to achieve clean casing windows in single trips, every time.